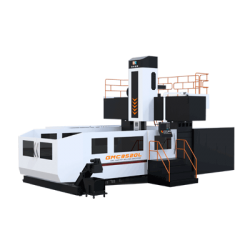

5 Axis CNC Machining

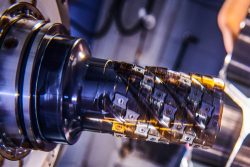

5 axis custom CNC machining service provided for the manufacturing of complicated geometrical parts for both metal and plastic. 5-axis One of the most cutting-edge methods accessible now is CNC machining. It uses subtractive machining to give part production a limitless range of options. Using this rapid machining services, workpieces are cut into the proper shapes and sizes using cutting tools that operate on five axes.

5 Axis CNC Machined Part

5 axis CNC machining is a process in which a CNC machine is capable of rotating around five different axes to produce complex and precise parts. This technology allows for greater flexibility and versatility in manufacturing compared to traditional 3 or 4 axis machining.

5 Axis CNC Machined Part

The main feature of 5 axis CNC machining is the ability to produce parts with complex geometries and shapes that would be difficult or impossible to create with other methods. This is achieved by the ability of the CNC machine to rotate around five different axes, allowing for more intricate and precise movements. Additionally, 5 axis machining can produce parts with higher accuracy and repeatability compared to other methods.

5 Axis CNC Machined Part

5 axis CNC machining is used in a variety of industries including aerospace, automotive, medical, and consumer goods. It is particularly useful in applications where parts require intricate and complex designs, such as turbine blades, engine components, and prosthetic limbs.

5 Axis CNC Machined Part

The advantages of 5 axis CNC machining include the ability to produce complex parts with high precision and accuracy, reduced setup times, increased productivity, and lower production costs. 5 axis machines can also produce parts with less waste and better surface finishes, which can reduce the need for additional finishing processes. This makes it a popular choice for companies looking to streamline their manufacturing process and improve their bottom line.

5 Axis CNC Machined Part

Advances in 5 axis CNC machining technology have allowed for increased precision, faster production times, and improved efficiency. Some of the latest advancements include the use of real-time monitoring and control systems, advanced tooling options, and the integration of automation and robotics. These advancements have made 5 axis machining even more versatile and cost-effective, making it a popular choice for high-end manufacturing applications.