5-axis Machining Center

Our 5-axis machining centers mainly include bridge 5-axis machining centers and vertical 5-axis machining centers, such as GB8550BF5, VB63F5.

The structure of our 5-axis machining centers is gantry type, which is high steady, high rigidity.

The design of our 5-axis machining centers is that the fixed parts are made from mineral casting and the traveling parts are made of high strength alloy steel which makes our machining centers have excellent precise retention, fast responsibility, and rapid traveling speed.

According to the workpieces, our 5-axis machining centers can choose the A/B swing head or the double swiving rotary table to achieve any angle positioning machining of the complex workpieces.

TYPES OF 5-AXIS MACHINING CENTER FOR SALE

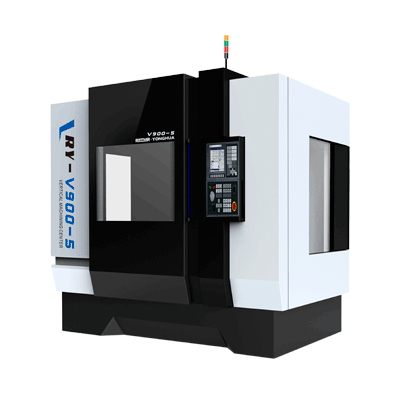

5 Axis Vertical Machining Center

5 Axis Gantry Machining Center

5-AXIS MACHINING CENTER ADVANTAGES

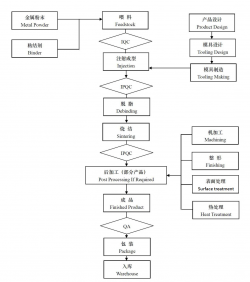

To make sure the highest precision, stability, and precision preservation of each machine, we take in new casting material UHPC and build our casting workshop. For the current manufacture of the company, all machine bases and columns are cast by UHPC strictly according to German casting standards.

Better Vibration Absorption

The vibration absorption of UHPC mineral casting is 10 times better than iron casting. Under a large dynamic load, the stability of machine precision can be guaranteed, while the surface finish quality of the workpiece can also be improved by 20%.

Excellent Thermal Stability

The thermal conductivity of UHPC mineral casting is 1/20 of that of iron casting, the specific heat capacity is 2.1 times that of iron casting. Excellent thermal stability and thermal inertia can effectively control any kind of machine deformation caused by temperature change, the stability of machine precision is further guaranteed.

High Rigidity

The moving parts are welded by high-strength low-alloy steel, the material elasticity modulus is around 1.4 times that of iron casting so that overall rigidity can be improved by more than 30%.

Lighter Weight

Compared to iron casting, the lighter-weight structure can reduce unit weight by 20%-30%, effectively reduce the inertia of moving parts and increase the dynamic response by 10-20%.

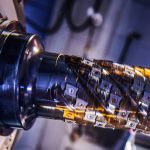

ATC System

The Vertical type 5-Axis is equipment with the chain type tool magazine driven by the servo motor, high running speed, high positioning accuracy that can greatly meet different processing requirements of customers. The tool sleeve running speed: 150 tool sleeves/min, capacity: 40T.

Auto-lubrication System

The machining centers are equipped with an auto-lubrication system that can auto lubricate the Linear Guide Rail, Block, Ball Screw, and Spindle at set time and volume, leaving no dead ends. The CNC machining center’s dynamic processing accuracy and stability are guaranteed.

Air Conditioner

The electrical cabinet has an air conditioner, which keeps a constant temperature that guarantees dynamic processing accuracy.

BRIDGE TYPE & VERTICAL TYPE 5-AXIS MACHINING CENTERS

Bridge type 5-axis linkage is achieved by the combination of the C axis inside the ram and the A-axis outside. C axis inside the ram can enlarge the process range. Several attached milling heads can be changed and installed in the C axis, which guarantees the consistency of the positioning axis. The A axis can be low energy big torque transmission through its structure of gear driven by the small motor.

Vertical type 5-axis machining centers structure is double swiving table that can make the 5-axis linkage and any angle positioning machining which meets the demand of the complex curved parts.