5-Axis Turn-milling Service

What is 5-axis CNC machining?

5 axis CNC machining is the process of using a CNC to move different parts or cutting machines across five separate axes at once. This makes it easy to produce highly complex parts, which is why 5-axis CNC machining is so common in aerospace operations.

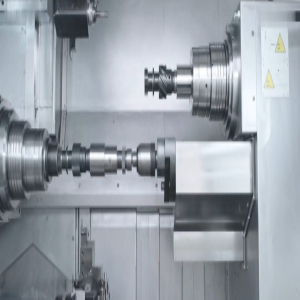

5-Axis CNC Turn-milling is the advanced version of CNC turn-milling, which can process parts in 5 axes. Both the production efficiency and precision are improved greatly.

Custom 5-axis CNC turn-milling parts

Milling is a process similar to drilling or cutting, using cylindrical cutting tools that can rotate along multiple axes-something you can’t do with traditional drilling. Utilizing computer numerical control can increase accuracy and make CNC 5-axis milling a reliable production method for creating shapes, holes, slots and impressions for your custom milled parts.

Our CNC milling machines can perform up to five axes of machining, providing +/-0.0002 inch accuracy on critical features. The 5-axis CNC milling machine is considered to be one of the most versatile milling machines available. It allows us to shape very complex parts and assemblies, such as aerospace and automotive parts, scale models, medical devices, etc. 5-axis machines allow parts to be completed with minimal setup, thus reducing the cost of simpler components.

Custom 5 axis CNC turned parts

CNC turning is another very common process for machining custom parts. It involves rotating the part on a lathe while a single-point cutting tool moves parallel to the axis of rotation, shaping the material as directed by a computer code programmed by our skilled precision engineers. Fast, efficient, detailed – and much more accurate than what can be achieved by hand.

Our machines can manufacture parts up to 680*450*400cm in size.