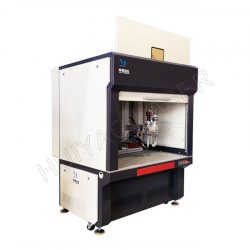

AQT-A900cap liner machine

AQT-A900cap liner machine

Various gasketsof different materials and different sizes to be inserted in caps (paper gaskets, aluminum foil gaskets, foam gaskets, etc.);

Cap liner insert machine feature:

1. Various gasketsof different materials and different sizes to be inserted in caps (paper gaskets, aluminum foil gaskets, foam gaskets, etc.);

2. Adopt PLC, module combination system, high efficiency and stability;

3. The linear design is convenient to replace the pressing head and accurate in alignment;

4. 2-2.5 seconds per working cycle, fast speed and high output;

5. Can identify and remove the empty and reverse cap automatically;

6. The recognition function for keeping the cap mouthalways up;

7. The feeding system can make the inversed caps fallingdown automatically, without stucking the cap;

8. Automatic stop and give an alarm when bottle cap in short supply;

9. The output can be seted according to the production demand, when the quantity is reached, the machine will stop and alarm.

Cap liner machine feature:

1. It replaces the handwork, avoids secondary pollution on the materials.

2. It adopts Siemens PLC which can ensure stable performances.

3. The machine can reject the defect caps automatically.

4. The sorting cap system puts the messy bottle caps in order, and makes all caps upward.

5. The machine can stop feeding automatically when caps are over supplied.

6. The system stops and alarms when caps are in short supply.

7. Automatically stops when reaching the set output.

Cap liner machine function:

The main function of cap lining machines is to automatically insert the aluminum foil gasket or the PE foam gasket into the cap,which achieves automatic liner inserting and prevents the liner from being contaminated by manual liner inserting.Automatic operation is not only environmentally friendly and sanitary,but also substantially improves the working efficiency of manufacturers.We can also customize special models according to customer needs.