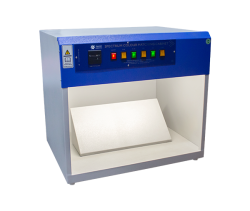

BHJG230 Bucking Machine

BHJG230 torque machine has six parts: driving clamp system、backup clamp system、hydraulic system、pneumatic system、manipulating platform and frame base.

Color: White Green

Material: Carbon Steel

Standard: API

Industries: Energy & Mining Machinery

Application: Casing Tubing Petroleum

PRODUCT DESCRIPTION

BHJG230 torque machine has six parts: driving clamp system、backup clamp system、hydraulic system、pneumatic system、manipulating platform and frame base.

The Driving clamp is driven by hydraulic motor and it is used to screw on and tighten (screw off) the coupling. The Buckup clamp is driven by pneumatic cylinder and it is used to fix the pipe. the screw on torque value is output by tension sensor and controlled by PLC system.

This machine can finish the work of 2″-7″diameter casing and tubing, the jaw plate includes: 2 3/8″— 2 7/8″— 3 1/2″— 41/2″—51/2″—7″, other sizes need to buy.

PRODUCT APPLICATION

BHJG230 torque machine produced by our company is special equipment used to screw on and off the coupling and pipe(tubing & casing).

FEATURES

1. BHJG230 torque machine is driven and controlled by hydraulic and pneumatic system, the system is easy and convenient to operate.

2. The system is controlled by hydromantic except for the driving clamp which driven by hydraulic motor, it can greatly reduce the oil leakage.

3. The Driving clamp uses closed structure, it is driven by hydraulic motor, the clamp head has 3 jaw plates with 120º distributing, every jaw plate has 2-3tooth, totally 6-9 tooth contacting the coupling surface, the teeth marks are according to API standard, the clamp head can reset automatically.

4. Back up clamp is similar to the driving clamp, but it is driven by the pneumatic cylinder .The driving clamp and backup clamp can regulate their center in one line automatically to meet the requirements of using.

5. It is easy to replace the dies

6. The backup clamp is equipped with tension sensor used to measure torque (the unit is KN.m). The control system will contrast the torque value and screw circles with the setting value, control the machine operating automatically.

7. Double pumps oil supply, adjust speed automatically, high speed screw, low speed torque, to meet the demand of special threads.

Please feel free to contact us if you need.

Model

BHJG230

Bore diameter

230mm

The applicable steel grade

H40, J55, K55, N80, L80, C90, C95, P110 and Q125.

Application

2″-7″

Applicable connections

API (round / buttress) threads or special thread(TS3SB, VAM, BDS, SEC, AB, ANTARES, T Blue, etc)

Variable speed range

Take double-pump as power, and the speed is stepless changed manually.The rotate speed of driving clamp:0.7-24r/min.

Max.screwing torque:30KN.M(when pressure is 16Mpa ).

Hydraulic system

Max.pressure

16MPa

Flow rate

10-180L/min

Pneumatic control system

Working pressure

0.4-0.8Mpa

Height of center

1100mm

Stroke of the moving cylinder

300mm

Dimensions

Main machine

3000mm×1350mm×1650mm

Hydraulic unit

2200mm×2050mm×1400mm

Control cabinet

1000mm×660mm×1020mm

OUR SERVICES

1. Best quality

2. Fast delivery

3. Professional technical support

4. We have been 15 years of experience in export sales.

5. We are machine reputable manufacturer, and also have after sales service.

FAQ

Q1. What about the payment?

A1: We accept L/C, T/T, D/P and Western Union payment terms.

Q2. Can you provide on-site installation and training for the machine?

A2: Yes, In special cases, we can provide installation, commissioning and training will guide your employees remotely via video.

Q3. How about your price?

A3: Please send me about what is your detailed request information, we will give you competitive prices in China.

Q4. What’s your warranty terms?

A4: The machine for one year warranty from the date of commissioning.