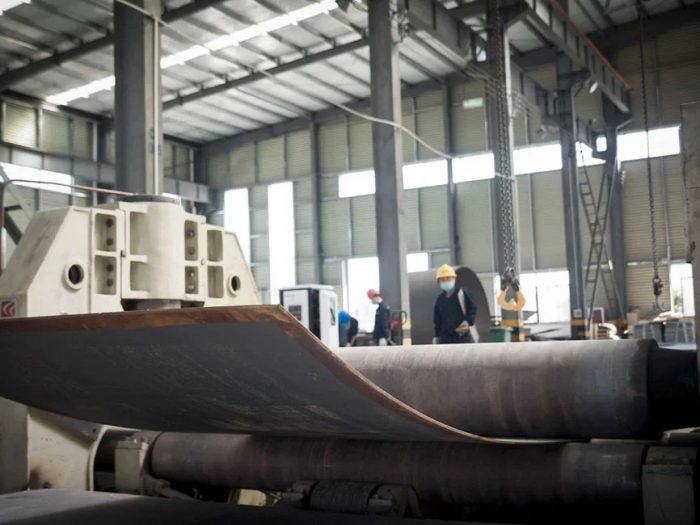

CLAD PLATE PROCESSING SERVICES

Gallianz is a professional supplier of clad plates. We are proficient in all the production processes. Each details are our advantages. We also offer a range of metal processing services:

Clad Plate Edge Peeling Service, Clad Plate Edge Beveling Service and Clad plate Coiling Service. If you need these special services, please contact and tell your requests.

Different Types Of Clad Plate Processing Services

What Is Clad Plate Processing Service

Clad plate processing service refers to the professional services offered by specialized companies to process clad plates according to customer specifications and requirements. These services involve various techniques and processes to cut, bend, weld, machine, or heat treat clad plates to achieve the desired dimensions, shapes, and properties.

Typically, clad plate suppliers have the expertise, equipment, and facilities to handle clad plates of different materials, thicknesses, and sizes. They work closely with clients to understand their specific needs and provide customized solutions. These companies may have the capabilities to handle complex projects and deliver high-quality clad plates that meet industry and customer standards.

The exact range of services provided by clad plate processing companies may vary but commonly include cutting (sawing, shearing, or plasma cutting), bending (press brake bending or roll bending), welding (TIG, MIG, or laser welding), machining (milling, drilling, or turning), and heat treatment (annealing, normalization, stress relieving).

By outsourcing clad plate processing services to specialized providers, customers can benefit from their expertise, efficient processes, and quality assurance. This allows customers to focus on their core operations while ensuring that they receive accurately processed clad plates that meet their specific needs.

Can Clad Plates Be Bent To Specific Shapes?

Yes, clad plates can be bent to specific shapes. The process of bending clad plates involves deforming the material to achieve the desired curvature or form. Clad plates are typically composed of layers of different metals or alloys bonded together, which can make them more challenging to bend compared to single-metal plates.

When bending clad plates, it is crucial to consider the properties and thicknesses of each layer to ensure that the bending process does not compromise the bond between the layers. The bending process must be carried out carefully to prevent delamination or separation of the clad layers.

Depending on the specific requirements, clad plates can be bent using techniques such as press brake bending or roll bending. These techniques apply pressure or force to the clad plate along a predetermined bend line, gradually forming it into the desired shape.

It is important to consult with experts or clad plate processing service providers who have experience and expertise in bending clad plates. They can provide guidance on the appropriate bending methods and ensure that the process is performed correctly, minimizing the risk of damage to the clad layers and maintaining the integrity of the bond.