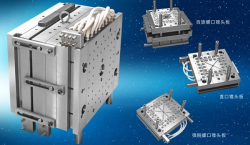

CLAMP BODY MOLD

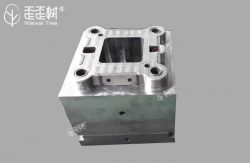

A Clamp Body Mold is a type of injection mold that is designed to produce the clamp body component used in clamping systems. The clamp body is a type of device used to hold two or more components together, commonly used in the automotive and electrical industry. The mold produces the clamp body component in the desired shape and size, which can vary based on the specific requirements of the end-use application. The clamp body mold is typically made of high-quality materials such as steel or aluminum, and it undergoes precision machining to produce accurate and consistent parts.

WHAT ARE THE FEATURES OF A CLAMP BODY MOLD?

A standard Clamp Body Mold typically has an efficient design, with one or more cavities and runners for accurate molten material flow. It provides a tight tolerance fit between mold halves to maintain the accuracy of the final product. The mold is often designed with cooling channels to ensure even cooling and reduce cycle times.

WHAT MATERIALS ARE USED TO MAKE CLAMP BODY MOLD?

The materials used to manufacture Clamp Body Mold are often high-quality and durable, such as steel, aluminum, or other high-strength alloys. The material used is dependent on the specific requirements of the end-use product, the rate of production required, and the complexity of the mold.