CNC MACHINING MATERIAL CHOICE

When it comes to CNC machining, selecting the right material is crucial for ensuring the quality and functionality of your parts. With a wide range of materials available, choosing the right one can be overwhelming. Here are some factors to consider when selecting materials for CNC machining:

Material properties: Different cnc materials have different physical and mechanical properties, such as strength, stiffness, toughness, and hardness. These properties affect the suitability of the material for specific applications.

Machinability: Some materials are easier to machine than others. For example, aluminum and brass are relatively easy to work with, while materials like titanium and hardened steel are more difficult.

Cost: The cost of the cnc machining material is also an important factor to consider. Some materials are more expensive than others, which can impact the overall cost of the project.

Application: Finally, the application of the part should be considered when selecting a material. Will the part be exposed to high temperatures, corrosive environments, or heavy loads? These factors can influence the choice of material.

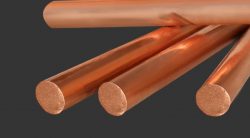

As a china high precision machining supplier, we can provide customized options for various materials, including stainless steel, carbon steel, aluminum, copper, POM, and other materials. The selection of suitable materials is crucial to ensuring the quality and functionality of the components. Therefore, we have professional procurement and a group of stable and outstanding suppliers who offer high-quality materials at competitive prices. Here are some commonly used customized materials we offer. For materials not listed, please feel free to contact us for more information. We could help you to select suitable materials with our professional expertise and customize a processing solution that meets your requirements.

Material Parameter Table

Material

Grade

Surface finishing processes

Material Range of Hardness and Strength

Scope of Application

Size

Stainless steel

301, 304, 316L, 305, 317, 420, 430, 440, 201, etc.

Polished, sandblasting, Frosted/Satin, electroplating, wire drawing, 8K, 12K, Mirror finish, Matte finish, BA, etc.

Hardness:170HV-650HVTensile Strength:780MPa-1780MPaYield Strength:470MPa-1450MPa

Mobile phone accessories, High-precision hardware materials, Etching specialty materials, Mechanical components, Automotive parts, High-precision instrument category, Household appliances, Daily necessities accessories, etc.

Customization

Carbon steel

Q195, Q215, Q235, Q255, Q275, etc.

Sandblasting, acid pickling, electroplating, chemical coating, etc.

Hardness:60HB-300HBTensile Strength:370MPa-2100MPaYield Strength:250MPa-1900MPa

Mold steel materials, Carbon steel mechanical parts, Automotive components, Heating appliances, etc.

Customization

Brass/copper

C5191, C1100, C63000, H62, H65, H70, HPB59, C36000, etc.

Polished, Frosted/Satin, 8K, 12K, Mirror finish, Matte finish, BA, etc.

Hardness:50HB-200HBTensile Strength:210MPa-620MpaYield Strength:50Mpa-480MPa

Force-bearing components manufactured by various stretching and bending processes

Customization

Aluminum

Series 1000, Series 2000, Series 3000, Series 4000, Series 5000, Series 6000, Series 7000, Series 8000, etc

Electroplating, Spraying/Painting, Brushing, Anodizing, Sandblasting, Passivation, Chemical Polishing, etc.

Hardness:60HV-120HVTensile Strength:175-470MPa

automation mechanical parts, precision component processing, mold manufacturing, electronics, and precision instruments, etc.

Customization

POM

common grades

—

—

medical equipment, sports equipment, power tool accessories, automotive components, electronic and electrical components, etc.

Customization