CNC Milling and Boring Machine

The maximal rotation of spindle can reach 2500rpm/min

It can meet the large-torque requirement during the rough machiningand the high rotational speed during the fine machining

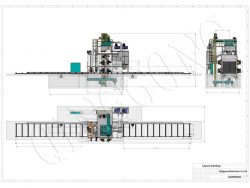

TYPES OF CNC MILLING AND BORING MACHINE FOR SALE

HB Series Horizontal Milling and Boring Machine

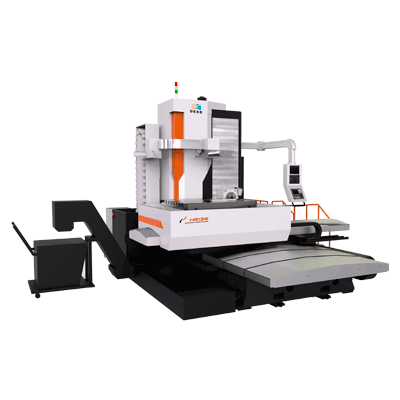

PBC Series Planer Type Milliling and Boring Machine

CNC MILLING AND BORING MACHINE ADVANTAGES

The double anti-backlash gearbox is controlled by a servo motor to drive the imported precision gear ring to rotate, and it is equipped with an angle grating ruler.

The spindle adopts high-precision SKF spindle bearings, equipped with spindle annular external cooling and spindle bearing dilute oil lubrication cooling technology, to ensure long-term high-precision operation of the spindle. Temperature sensors are designed at the front and rear ends of the spindle bearing to monitor the temperature of the spindle bearing in real-time to prevent damage to the bearing due to excessive bearing temperature.

MINERAL CASTING VS. TRADITION IRON CASTING MATERIAL

Compare with traditional iron casting material, mineral casting vibration absorption is 10 times better than iron casting, stability.

And with higher heat stability. Mineral casting thermal conductivity is 22 times lower than iron casting. The influence of temperature is less.

WHAT IS A BORING MACHINE USED FOR?

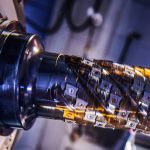

The boring machine is the main equipment for processing large box parts, and its processing accuracy and surface quality are higher than drilling machines. It is mainly a machine tool that uses a boring tool to boring holes on a workpiece. Generally, the rotation of the boring tool is the main motion, and the movement of the boring tool or the workpiece is a feed motion. Mainly used in heavy machinery industry, crane manufacturing industry, heavy construction machinery manufacturing industry, large electromechanical industry, petroleum industry, valve machinery industry, aircraft, ship machinery manufacturing industry, etc.

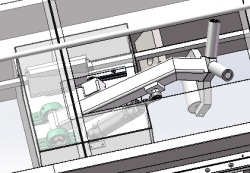

WORKING PRINCIPLE OF BORING MACHINE

A boring machine is a machine tool that uses a boring tool to boring holes on a workpiece. Generally, the rotation of the boring tool is the main motion, and the movement of the boring tool or the workpiece is the feed motion. Its machining accuracy and surface quality are higher than drilling machines. A boring machine is the main equipment for processing large box parts. Processing characteristics: The workpiece does not move during processing, the tool is moved, the tool center is aligned with the hole center, and the tool rotates (main movement).