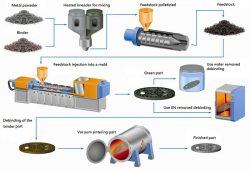

COMMON PROBLEMS AND CORRESPONDING SOLUTIONS OF INJECTION MOLDING FOR BUMPERS

With the rapid development of the automotive industry, plastic parts are used more and more widely in automobiles. The application of automotive plastic parts has significant advantages in terms of reducing the quality of cars, saving fuel, promoting environmental protection, and recyclability. Most automotive plastic injection molding parts adopt injection molding processes, such as bumpers in BMW cars. However, tiger skin patterns, poor surface replication, sink marks, weld lines, warping deformation, etc. are also common defects in automotive injection molded parts. These defects are not only caused by materials, but also have a lot to do with the structural design, mold design and molding process. Here are some common problems and solutions for bumper injection molding.

2. Common problems and corresponding solutions of injection molding for bumpers

(1) Pressure line

There are obvious pressure lines around the bumper fog lamps, which affect the appearance and surface quality of the product. Because the bumper is part of the outer surface of the car, it has strict requirements on the apparent quality, and the pressure line will have a serious impact on its apparent quality.

Possible cause analysis and improvement measures:

a. Mold: a gate G5 is set near the hole around the fog lamp. When this gate is opened, due to the influence of the hole, the pressure on both sides of the hole will reach a balanced pressure line again.

b. Solution: try to reduce the pressure difference around the weld line, or make the pressure difference insufficient to push the solidified melt to move.

(2) Tiger skin pattern

Tiger skin pattern is a surface defect of wavy stripes, which is approximately perpendicular to the direction of melt flow, forming markings with different gloss on the surface of the part, which looks like the pattern on the skin of a tiger, commonly known as tiger skin pattern.