Cottonseed Oil Press Machine

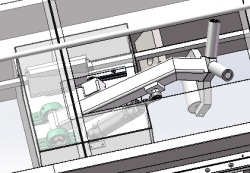

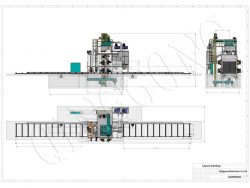

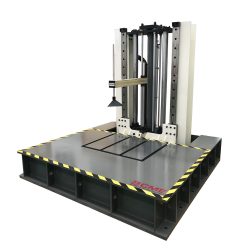

Cottonseed oil expeller machine is mainly composed of electrical control, automatic heating, adjustment, transmission, and vacuum oil filter. The screw is carburized by alloy steel to enhance surface hardness and wear resistance. The platter is ground by the surface grinding machine to ensure the finishing coat and increase the oil output. The surface of the machine is treated with stainless steel and chromium plating, meeting food hygiene standards. The commercial importance of the seed of cotton lies in its oil and other products. Cottonseed oil can be used as salad oil and cooking oil. After oil extraction, the residue or seed kernel can be used as livestock feed. Use a cotton gin to remove short lint from seeds. It can then be used to make roving and various fiber products. Seed hulls can be used as coarse feed for animals. Although the ancient Chinese and Indians used crude methods to extract cottonseed oil for medicine and lighting, large-scale industrial use is a new development. Cottonseed is the seed of a cotton crop. The exterior of cottonseed is a hard brown seed shell, and its shape and size vary with the variety. The seed shell contains the embryo, which is the main part of cottonseed, also known as the seed kernel. The oil content of seed kernels can be up to 35-45%, containing about 39% protein and 0.2% gossypol. The cottonseed oil machine can press all oil crops continuously: soybean, peanut, rapeseed, sesame, palm seed, sunflower, cottonseed, tung seed, coconut, olive, rice bran, palm tree, corn husk, etc.

1. Advanced technology and long life

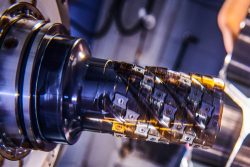

A steel casing is added at the main shaft of the speed reducer of cotton oil mill machinery. Press cage to change single bar to double bar. Adopting high-quality steel, through carburizing quenching or high-frequency quenching, it has the advantages of high hardness, good wear resistance, high precision, running balance and no noise. It satisfies the long-term continuous automatic production and can be used for more than 30 years.

2. High oil yield and large output of cotton oil mill machinery:

The cotton oil mill machinery uses the world’s advanced enhanced pressure structure cutters circular row. The pressure of barrel is high. The newly developed four-stage and five-stage compression, the pressure is higher. Their oil yield of soybean is up to 18%, second to none in China.

3. Low energy consumption, labor-saving:

Cotton oil mill machinery adopts infrared heating. It automatically controls temperature, reduces heat loss and shortens heating time. The transmission adopts planetary gear, the first in China. It greatly reduces energy consumption by more than 30 percent. Cottonseed oil machine can achieve automatic control of electrical production and reduce operating personnel.