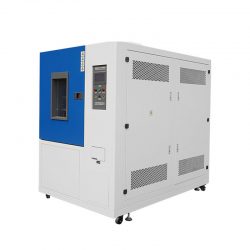

Creating Controlled Environments: The Role of Temperature Test Chambers

Temperature test chamber is highly valuable tools used in various industries to assess the effects of temperature on products and materials. These chambers provide controlled environments that allow manufacturers to evaluate product performance, reliability, and durability under different temperature conditions. In this article, we will explore the significance of temperature test chambers and their practical applications.

Understanding Temperature Test Chambers: Temperature test chambers are enclosed chambers equipped with precise temperature control systems. They can simulate extreme temperature conditions, ranging from extreme cold to high heat, to create the desired testing environment. These chambers enable manufacturers to study how materials and products respond to temperature variations and make informed decisions about design, quality, and performance.

Applications of Temperature Test Chambers:

Electronics and Electrical Industry: Temperature test chambers play a crucial role in the electronics and electrical industry. These chambers enable manufacturers to assess the performance and reliability of electronic components, such as PCBs, semiconductors, or batteries, under different temperature conditions. By subjecting these components to extreme temperatures, manufacturers can identify potential failures, improve designs, and optimize the performance and lifespan of their products.

Automotive and Aerospace Industries: Temperature test chambers are extensively used by the automotive and aerospace sectors. These industries require components and materials that can withstand extreme temperatures encountered during operation. By subjecting vehicle parts, such as engines, brakes, or electrical systems, to controlled temperature environments, manufacturers can evaluate their durability, thermal stability, and performance. This helps ensure the safety and reliability of vehicles even in challenging conditions.

Pharmaceutical and Life Sciences: Temperature control is critical in the pharmaceutical and life sciences industries. Temperature test chambers are employed to simulate storage conditions for drugs, vaccines, and other medical products. These chambers ensure that pharmaceutical products can maintain their efficacy and stability under various temperature conditions, especially during transportation and storage. By conducting temperature tests, manufacturers can ensure the quality and safety of these products.

Material Testing and Development: Temperature test chambers are essential tools for material testing and development. Manufacturers and researchers can assess the behavior and properties of different materials, such as plastics, metals, or composites, at both high and low temperatures. By conducting temperature tests, they can understand how materials expand, contract, or exhibit changes in mechanical properties, aiding in the selection of suitable materials for specific applications.

Conclusion: Temperature test chambers play a vital role in various industries by providing controlled environments to study the effects of temperature on products, components, and materials. From electronics to automotive, pharmaceuticals to material testing, these chambers enable manufacturers to evaluate how different materials and products perform under extreme temperature conditions. By utilizing temperature test chambers, companies can improve product reliability, optimize designs, and ensure the quality of their offerings, ultimately enhancing customer satisfaction and maintaining a competitive edge in the market.