Custom Overmolding & Insert Injection Molding Services

Zhongde, a reputable plastic and rubber injection molding company in China, also manufactures customized over-molding and insert molding, with considerate services, to produce unique multi-material parts. Our production materials of custom over-molding and insert molding range from thermoplastic to elastomer-rubber, as well as metal and silicone. We’ve broken down the differences and similarities between the two processes. Let us help you decide which process is right for your project.

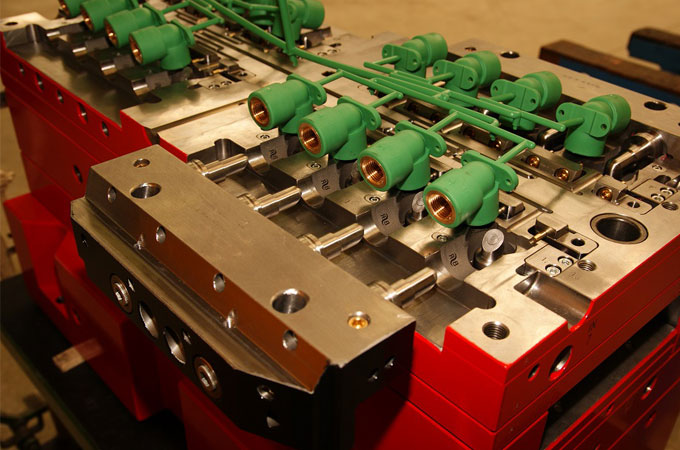

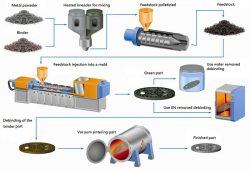

Both over-molding and insert molding injection processes by Zhongde, a reliable injection molding supplier, involve putting two types of materials together to make one part. And the inserts can be threaded metal inserts. Overmolding is a two steps process that one to create the substrate and one for the oversold that goes on top of it. Insert molding is a slightly faster process as it takes only one step that the two materials are molded at the same time.

Overmolding & Insert Molding

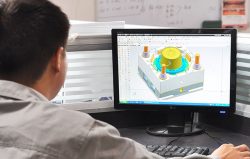

Guideline Of Overmold & Insertion Injection Moulding

Overmolding is a process where a single part is created using two or more different materials in combination. Traditonally, overmolding starts with injection molding a hard plastic resin that has a higher melting point. Once that part is cooled, another material is injection molded over the first part, resulting in a single, finished product.

Insert molding combines metal and plastic injection molding service into one single part. It allows plastic to bond to insert pieces, mostly brass or stainless steel metal component, which go inside a mold cavity. There are many options for insert that can be placed into the mold. A few of examples are warming labels, threaded bushings, wires, batteries, etc.

Size of Molding Over & Insert Injection Molding

Below table shows the size of Overmolding & Insert Molding parts we usually make. If you need a larger size, we can also help you achieve it.