Detergent Grade CMC

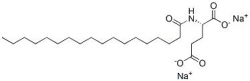

Detergent grade CMC is a type of sodium carboxymethyl cellulose that is specifically designed for use in the detergent industry.

CMC is a water-soluble polymer made by chemically modifying natural cellulose. Detergent grade CMC is commonly used as a thickener, stabilizer, and dispersant in various types of detergent formulations, including laundry detergents, dishwashing detergents, and industrial cleaners.

Use Of CMC In Detergent

Detergent grade CMC has several properties that make it ideal for use in the detergent industry. These include:

High water solubility: Detergent grade CMC is highly water-soluble, which helps to improve the dissolution and dispersion of the detergent in water.

Thickening and stabilizing properties: Detergent grade CMC can thicken and stabilize the detergent formulation, improving its viscosity and preventing phase separation.

Excellent dispersibility: Detergent grade CMC can disperse and suspend soil particles and other contaminants, improving the cleaning performance of the detergent.

Compatibility with other ingredients: Detergent grade CMC is compatible with a wide range of other ingredients commonly used in detergent formulations, making it a versatile and flexible additive.

CMC For Detergent For Sale

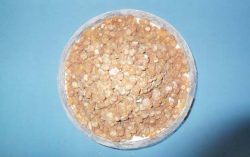

CMC FD7

KimaCell® CMC FD7 sodium carboxymethyl cellulose (CMC-Na) is a carboxymethylated derivative of cellulose.

CMC FD40

KimaCell® CMC FD40 sodium carboxymethyl cellulose is referred to as CMC or SCMC, also known as cellulose gum, which is the most important ionic cellulose gum and an anionic linear polymer substance.

How To Use Detergent Grade CMC?

The specific usage and dosage of detergent grade CMC may vary depending on the application and other factors, such as the type of detergent formulation and processing conditions. it’s important to follow standard safety procedures when handling and using detergent grade CMC, including using appropriate protective equipment and handling it in a well-ventilated area.

Here are some general guidelines for using detergent grade CMC:

01.

Determine the appropriate dosage: The optimal dosage of detergent grade CMC depends on the specific application and desired properties. Typically, dosage levels range from 0.1% to 1.0% by weight of the detergent formulation.

02.

Prepare the detergent formulation: The detergent formulation should be prepared according to standard industry procedures, and the CMC should be added slowly and evenly while stirring.

03.

Mix thoroughly: After adding the detergent grade CMC, the formulation should be mixed thoroughly to ensure that the CMC is evenly distributed throughout the material.

04.

Adjust the rheology: If necessary, the rheology of the detergent formulation can be adjusted by adding more or less CMC. Rheology modifiers such as deflocculants or dispersants may also be added to achieve the desired rheology.

05.

Test the final product: After processing, the final detergent formulation should be tested to ensure that it meets the desired properties and performance criteria, including viscosity, stability, and cleaning performance.

![ECHEMI | 2-[methoxy(methyl)amino]ethyl 4-aminobenzoate](https://salesale.sale/btabcloud/uploads/2022/08/methoxymethylaminoethyl-aminobenzoate-1659598232pc4l8-250x250.png)