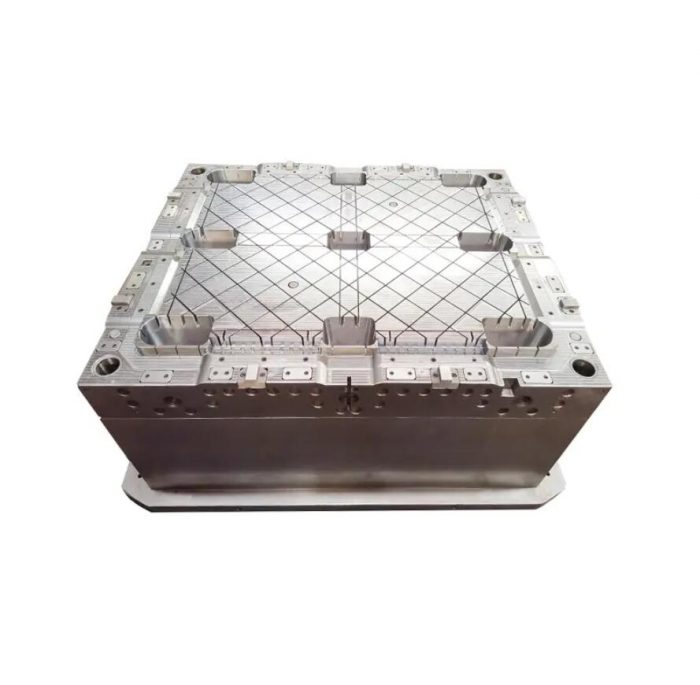

Durable Heavy-duty Plastic Pallet Injection Mould

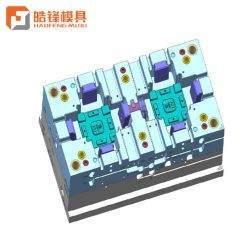

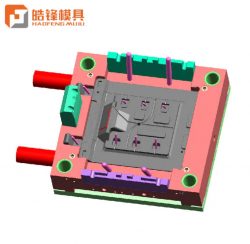

Our company specializes in manufacturing all kinds of plastic pallet injection moulds, and specializing in customizing plastic pallet moulds of various sizes and styles.Pallet molds are widely used, and plastic pallets play an important role as an indispensable part of the warehousing and logistics industry.It plays an increasingly important role in warehousing logistics and distribution. It is an important tool for modern transportation, packaging and warehousing. It is suitable for use in various factories, distribution centers and three-dimensional warehouses.Our plastic pallet is suitable for environmental protection, and it has high load-carrying performance and long service life.Our company has accumulated a lot of experience in manufacturing plastic pallet injection mould. Welcome domestic and foreign customers to inquire about custom molds.Mould material#45, high-quality Shanghai Baosteel P20 (hardness 28-32hrc) and 718 (hardness 32-38hrc) are selected for general productsPallet mold customizationCustomized molds can be made according to customer requirements, and sample processing.Customization Instructions1. The customer provides drawings or product samples, and we preliminarily calculate the price.2. The customer confirms the price, receives the customer’s deposit, connects with the technology, and conducts product analysis.3. Both parties confirm the final drawings and technical parameters. Carry out mold design and processing.Process typeInjection molding mold.Design softwareMoldflow, UG, PROE, AUTOCAD, etc.Plastic materialPP, PEMain processing equipmentCNC, CNC milling machine, God drilling, milling machine, grinding machine, fine carving, wire cutting, EDM.Number of cavitiesSingle cavityGateHot runner, cold runnerWaterwayThe scientific and reasonable waterway arrangement design can increase the cooling effect by 30%, ensure that the mold is cooled evenly during production and molding, effectively shorten the production cycle, and prolong the service life of the mold.Mold ProcessingNitriding – reducing the deformation of the mold, increasing the surface hardness and wear resistance of the mold, making the mold more durable and extending the life of the mold.Electroplating—increases the brightness and corrosion resistance of the molding surface, and is practical for some transparent parts with high surface requirements.Skin texture – make texture on the surface of the mold, so that the product can be more textured, it is very suitable for luggage.Mold life45# :300,000-500,000 shots /P20: 500,000 shots / 718: 700,000 shotsMould PackagingWooden BoxProduction cycle45-90 daysOriginZhejiang · Taizhou Huangyan

our website is https://www.mould-factory.net/