Eaton Char-Lynn Motor – Construction Machinery Motor Overhaul: 3 Points

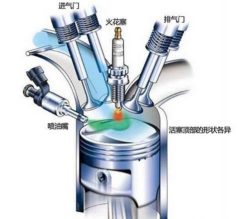

1. Measurement of cylinder liner wear

The general process of motor cylinder liner measurement is: select the gage according to the nominal size of the cylinder liner, that is, the micrometer and the cylinder table (including the plunger of the cylinder table); install and adjust the gage, that is, adjust the micrometer to the nominal size of the cylinder liner. Then, the measuring rod and the plunger of the cylinder table of the dial gauge are clamped between the anvil and the measuring rod of the micrometer, and the extension length of the cylinder table insert is adjusted, when the small needle of the dial gauge has Lock the plunger lock nut when the preload is about 1.5-2.0 squares, and adjust the large dial of the dial gauge to zero;

Determine the measurement position and direction of the cylinder liner; measure and record the data and process it. Finally, propose the repair method. When installing and adjusting the gauge, the anvil and the end face of the probe are small, slightly Caution or very slight interference and jitter will cause the plunger and the measuring rod of the cylinder table to come off the anvil and the end face of the micrometer, so that the adjustment fails and has to be re-adjusted, so the adjustment work is time-consuming and labor-intensive, and the work efficiency is extremely low. Moreover, the operator is given a feeling of “unskilled business and awkward movements”, which not only affects the progress and smoothness of the inspection, but also affects the operator’s image of practicing.

In response to this situation, the Eaton Char-lynn Motor believes that the operation can be improved: when installing and adjusting the gage, first adjust the dry ruler to the nominal size of the cylinder liner, then install the card to the dial indicator and install it initially. The cylinder of the rod directly enters the minimum wear of the cylinder liner to be measured, and the extension length of the cylinder rod of the adjustment cylinder is adjusted so that the gauge needle of the cylinder meter has a preload of about 1.5-2.0 grid and the cylinder The plunger lock of the watch is locked, and finally the measuring rod and the plunger of the cylinder table are clamped between the anvil and the measuring rod of the micrometer and the large dial of the dial gauge is adjusted to zero.

This adjustment method is to change the adjustment of the cylinder table from the full card on the scale to the part on the scale, and the other adjustment is in the area of the anvil and the probe end face relative to the micrometer. The infinite cylinder liner is carried out, thereby effectively shortening the adjustment time of the cylinder table on the micrometer, avoiding the time-consuming and laborious problem of the above conventional adjustment method, and significantly improving the anti-interference and operability of the gauge adjustment work.

2. The measurement of the clearance between the cylinder liner and the piston is generally considered to have at least the following three methods for measuring the clearance between the cylinder liner and the piston of the motor:

(1) The conventional method is to measure the inner diameter of the cylinder liner and the outer diameter of the piston skirt separately, and the difference is the matching clearance between the cylinder liner and the piston of the motor.

(2) Firstly measure the outer diameter of the piston skirt directly with a micrometer, and then install the dial gauge and the cylinder head card with the preliminary installation of the plunger between the anvil and the measuring rod of the micrometer, and adjust the cylinder table. The extension length of the plunger, when the small gauge of the dial gauge has a preload of about 1.5-2 grids, lock the plunger locker, and adjust the large dial of the dial gauge to zero, and finally the gauge cylinder extension In the cylinder liner, the dial gauge has a lower value than “zero” (considering the small gauge reading) is the matching clearance between the piston and the cylinder liner.

(3) Firstly measure the outer diameter of the piston skirt directly with a micrometer and turn the dry scale stop screw to the locking position, then directly insert the card with the dial indicator and the cylinder table of the preliminary installation of the plunger. Corresponding to the cylinder sleeve, adjust the extension length of the cylinder table plunger, so that the small needle of the dial indicator has a preload of about 1 grid and lock the plunger lock, and adjust the large dial of the dial gauge to zero. Finally, the measured rod and the plunger of the adjusted cylinder table are stuck between the anvil and the measuring rod of the dry gauge, and the dial gauge has a higher value than “zero” (considering the small gauge reading). It is the matching clearance between the piston and the cylinder liner.

It can be seen from the above measurement methods that the methods (1) and (2) have the same problem that the cylinder table is completely adjusted on the micrometer and the operability is poor, and the third (3) measurement The method is similar to the operation skill of the cylinder liner measurement, and it is worthy of the operator’s preferred choice. Similarly, this technique can be used for the measurement of the clearance between the crankshaft journal and the crankshaft bearing.

3. On-hand treatment of broken head cylinder head bolts

When handling the broken head cylinder head bolts, if the metal parts are not carefully noticed, the metal debris generated during the treatment may easily fall into the cylinder or the oil hole, causing extreme abrasive wear in the later use, which seriously affects the service life of the motor. In order to prevent this, when removing the broken bolt on the cylinder head, a visor can be made by using the green paper or ordinary cardboard in the style of the cylinder head gasket. During the production, the cylinder head pad is dipped with a little waste motor oil and then printed on the paperboard, and then the hollow hole corresponding to the size of the cylinder head bolt is used to cut out the hole at the screw hole position of the cardboard printing (the rest is like the cylinder mouth position, water passing through) The rubbing of the hole and the position of the oil hole is not smashed. Finally, the edge of the cardboard can be trimmed with scissors. In use, the visor is placed above the cylinder, and the cylinder head bolt is inserted out through the opening of the corresponding visor, so that the visor is attached to the upper surface of the cylinder; then, the detachment is broken according to the general disassembly method. Bolt; Finally, use a brush to carefully clean the metal chips that fall on the visor and remove the visor.

https://www.xjetl.com