Eaton Char-Lynn Motor – Efi Motor: 2 Causes Of Failure

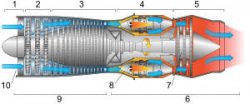

The motor must start with three elements: compression, sparks, and a mixture. If an element works abnormally, it will cause the motor to fail to start or start up. There are many factors that cause the EFI motor to start to fail. The faults analyzed by the Eaton Char-lynn Motor occur when the battery voltage, the starting system is working properly, the motor has good compression and spark, and the exhaust purification device is working properly.

The startup failure generally manifests as difficulty in starting and starting, and the difficulty in starting is divided into difficulty in cold start and difficulty in hot start.

Can not start

The motor can’t start and there is no sign of fire. It is usually caused by the lack of fuel injection. The main reasons are as follows:

1, the speed signal system failure

The motor speed and crankshaft position sensors detect their speed signals while the motor is running, provide crankshaft position signals, and serve as the main basis and basis for the control system to perform various controls. If the sensor or its line fails, the electronic control unit cannot receive the speed signal and the crankshaft position signal, and the fuel injection and ignition timing cannot be correctly controlled. The injector does not operate and the spark plug does not jump. Check with the stethoscope and the timing light to confirm that the injector and spark plug are working.

When the above fault occurs, the general self-diagnosis system can display the fault code and comprehensively check the speed sensor, the 1 and 2 camshaft position sensors and their lines. First disconnect the connectors of each sensor and check their resistance. If the resistance is not normal, they must be replaced. If it is normal, check whether the wiring and connectors of the ECU and each sensor are normal.

2, fuel pump and control circuit failure

If the fuel pump or control circuit fails, it will also cause the fuel supply system to have no fuel pressure. Even if the injector is working properly, the fuel cannot be injected normally. Check the method: connect the diagnostic plug-in terminals +B and FP with a short wire and turn on the ignition switch (do not start) to check the pressure in the oil inlet hose. If there is pressure in the hose and the oil can be heard, the fuel pump itself has no problem; otherwise, the fuel pump should be checked, and the resistance between terminals 4 and 5 can be measured with a multimeter. If it does not match the specifications, the fuel pump needs to be replaced. . If the fuel pump is working properly, its control circuitry should be checked, including fuses, EFI main relays, fuel pump relays, resistors, and wiring and connectors. [

Hard to start

The influencing factors and inspection methods for the difficulty of cold start and the difficulty of hot start are generally the same. As far as the concentration of the mixed gas is concerned, there are two cases where the mixed gas is too lean and the mixed gas is too rich. Faults affecting fuel supply may occur in fuel quality, fuel pump, fuel filter, fuel pressure regulator, cold start system, fuel injector and water temperature sensor; failures affecting intake air are often caused by air filter blockage, Air intake system air leakage and idle speed control failure.

1. Fuel pressure regulator failure

The oil pressure of the fuel system has a direct effect on the concentration of the mixture, so the fuel pressure should first be checked. The method is: first connect the fuel pressure gauge into the fuel line, then start the motor and measure the fuel pressure. If the fuel pressure is too high, the pressure regulator should be replaced; when the pressure is too low, the return hose can be clamped. If the fuel pressure rises to a normal value, the fuel pressure regulator is damaged, otherwise the fuel pump and fuel filter can be checked. . Check the fuel pressure after shutdown to maintain the specified value for 5 minutes, otherwise the injector leaks, resulting in excessive mixture.

2, fuel pump and fuel filter failure

When the starting is difficult, the general fuel pump can work normally. The problem is that the oil pump filter is clogged, so that the oil pump can not inhale enough fuel or the fuel filter is not smooth, causing insufficient pressure in the oil supply system.

3, cold start system failure

In some models, there is a cold start injector that thickens the mixture during cold start to improve cold start performance. The cold start injector is controlled by a start switch and a thermal time switch. The duration of the injection depends on the thermal coil current and the temperature of the cooling water.

The cold start system failure is characterized by: the cold start injector is blocked by the glue, affecting the quality of the spray atomization, which makes the cold start difficult; the cold start injector fails to work normally; the thermal time switch is shorted (contact Normally closed) or open circuit (normally open). If the contact is normally closed, the hot starter still controls the cold start injector to inject too much fuel, which makes the hot start difficult. If the time switch is shorted, the cold start injector always Failure to work can make cold start difficult.

4, injector failure

The injector failure is generally manifested as: the injector nozzle is blocked by the colloidal object, and the carbon deposit or the sealing is not strict, causing the drip, resulting in the mixture concentration being too small or too large. The detection method is: first start the motor, check the operation sound at each injector with a stethoscope, if the sound is not heard, check the wiring connector, the injector or the injection signal from the ECU; then, measure with a multimeter If the resistance between the injector terminals does not match the specified value, replace the injector. Finally, check the fuel injection amount of the injector. The value should be within the normal range and the difference between the injection quantities of each cylinder is less than 5cm3. .

5, water temperature sensor failure

The water temperature sensor is used to detect the temperature of the cooling water and convert it into a temperature-dependent voltage signal input to the ECU as a basis for the ECU to correct the fuel injection amount. If the water temperature sensor fails or the wiring between the ECU and the ECU is broken, the short circuit, and the surface scale is serious, the output signal will be greatly deviated, and finally the injector will not increase or decrease the fuel injection amount in time, resulting in difficulty in starting.

6. Idle speed control valve (ISC) failure

Most EFI motors use a stepper motor type idle speed control valve. The ECU adjusts the energization sequence of the stepper motor solenoid coil according to the operating conditions of the motor, so that the cone valve body on the stepping motor shaft is screwed in or out. The opening of the bypass air passage is used to adjust the bypass intake air amount.

If the motor is difficult to start but can be started by stepping on the throttle, the idle control valve is faulty. Disassembling the ISC valve will result in more carbon deposits, colloidal viscosity, and oil accumulation on the tapered surface of the valve body. As a result, the adjustable range of the conical valve is reduced, resulting in a decrease in intake air and a mixture when the cold car is started. Excessive concentration and difficulty in starting up.

https://www.xjetl.com