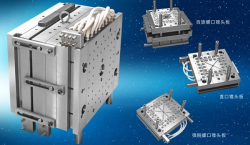

Electrical Product Power Mould

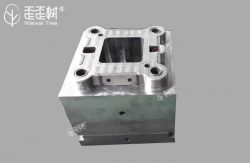

Electrical product moulds or power moulds are critical components in the production of high-quality electrical components and devices for power transmission and distribution systems. YF POWER is a leading brand that offers reliable electrical product moulds/power moulds designed to meet the specific requirements of electrical components and systems. These moulds are made of high-grade materials, including steel, aluminium, and copper alloy, and are manufactured with advanced production technologies such as CNC machining, EDM, and wire cutting. The use of these moulds ensures the optimal production of electrical components with precise dimensions, complex shapes, and high-repeatability rates.

YF POWER’s electrical product moulds/power moulds are engineered to meet the highest quality standards, ensuring the longevity and reliability of the products manufactured using these moulds. These moulds are widely used in the power industry, including the production of insulators, bushings, and surge arresters, among others. YF POWER’s electrical product moulds/power moulds provide efficient and cost-effective solutions for the production of high-quality electrical components, ensuring safe and reliable power transmission and distribution systems.

Types of Electrical Product Power Mould

Arrester Mould

10kV Arrester Mold (1-8)

36kV Arrestor Mold (1-6)

Insulator Mould

3kV Insulator Mold (R-1-8)

24kV Insulator Mold (R-1-6)

35kV Insulator Mold (R-1-6)

66kV Insulator Mold(1-2)

500 kV Insulator Mold

1000 kV Insulator Mold

Hollow Core Mould

110kv Hollow Core Mould

150kv Hollow Core Mould

Portable Variable Frequency Test System

Impulse Voltage Test System

AC Test Transformer System (Oil Insulated Type)

HV DC Generator Test System

AC Resonance Test System (Variable Inductance)

AC Test Transformer System (GAS Insulated Type)

Variable Frequency Resonance Test System(Gas Insulated Type)

Cable Accessory Mould

Cold Shrinkable Mould

Hot Shrinkage Mould

Cut-Out Insulator Mould

Benefits of Electric Product Mould/Power Mould

Precision and Consistency

Electric product molds are engineered with precise specifications, ensuring that each finished product meets consistent requirements. This reduces the possibility of defects and inconsistencies in the manufacturing process.

Longevity and Durability

Electric product molds are created using high-quality materials, ensuring a durable and long-lasting lifespan. As a result, this helps reduce costs for businesses in the long run through fewer replacements and more consistent outputs.

Customization

Power moulds can be customized to fit the specific needs of a product client, allowing for increased flexibility in manufacturing processes. Custom design renders improved performance, distinct shape, and innovation that helps products stand out from others in the market.

Cost-Effectiveness

Electric product moulds can be designed and produced at scale, reducing costs for businesses in the long run through options to use existing non-standard molds or to develop standard mold sizes, making them a cost-effective solution for businesses that produce high-volume parts. The cost-effectiveness in mould production allows manufacturers to make their products affordable while maintaining quality standards.

Working Principle of Electric Product Mould/Power Mould

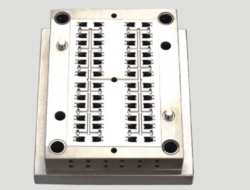

Electric product moulds or power moulds are tools used to create a specific shape or design for an electrical product. The moulds are created with the customer’s specifications in mind and are designed to accurately produce parts and components that meet precise requirements. The working principle of electric product moulds is straightforward. The mould is created with a cavity or a set of cavities that match the desired shape of the final product. Once the mould is in place, the liquid material is injected into the cavity, taking up the space occupied by the mould.

Once the material cools or solidifies, the mould is removed, leaving a finished part with the exact shape and design specified by the client. Using electric product moulds helps ensure that the quality and consistency of electrical products remain uniform in every production batch. Moreover, power moulds can now be designed and customized to provide automation, reduction in human errors, and a high level of precision in production processes.