Evaluating Durability: The Importance of Abrasion Testers

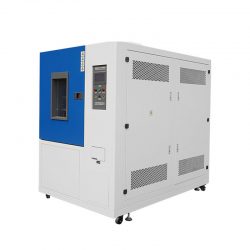

abrasion tester, also known as wear testers or abrasion resistance testers, are valuable tools used in various industries to assess the durability, wear resistance, and lifespan of materials and finished products. These testers simulate abrasive conditions to evaluate how materials withstand repeated friction and rubbing. In this article, we will explore the significance of abrasion testers and their practical applications.

Understanding Abrasion Testers: Abrasion testers are designed to measure the resistance of materials to abrasion, such as scratching, rubbing, or wear caused by external factors. These testers apply controlled levels of friction and replicates real-world conditions to evaluate the durability and performance of materials. The results obtained from abrasion tests provide valuable insights into the material’s ability to withstand wear and tear, helping manufacturers make informed decisions about material selection, design improvements, and quality control.

Test Methods: Different abrasion testers employ various test methods based on the specific application and industry requirements. Some commonly used methods include:

Taber Abrasion Test: The Taber abrasion test utilizes a rotating abrasive wheel or a pair of abrasive disks to subject the material to repeated friction. This test assesses the material’s resistance to abrasion by measuring the weight loss or the number of revolutions required to wear through a specified layer. The Taber test is widely used for evaluating the wear resistance of coatings, flooring materials, plastics, textiles, and other surfaces.

Martindale Abrasion Test: The Martindale abrasion test is primarily used for textiles and fabrics. It involves placing the sample fabric in contact with an abrasive pad during a circular rubbing motion. The test measures the level of abrasion, typically expressed as the number of cycles required to cause noticeable wear or damage to the fabric.

Applications of Abrasion Testers:

Textile and Apparel Industry: Abrasion testers play a crucial role in the textile and apparel industry to assess the durability and wear resistance of fabrics, threads, zippers, buttons, and other textile products. By subjecting fabrics and materials to controlled friction, manufacturers can evaluate their suitability for different applications, such as clothing, upholstery, or outdoor gear.

Automotive Industry: The automotive industry relies on abrasion testers to evaluate the wear resistance of materials used in vehicle interior components, such as seats, carpets, steering wheels, and dashboard panels. These tests help determine the longevity and performance of these materials under constant use and exposure to friction.

Flooring Industry: Abrasion testers are used to evaluate the wear resistance and durability of various flooring materials, including laminates, vinyl, hardwood, or ceramic tiles. These tests simulate foot traffic or abrasive contact to assess the material’s ability to withstand wear and retain its appearance over time.

Coating and Paint Industry: Abrasion testers are employed to assess the resistance and durability of protective coatings, paints, varnishes, or surface treatments. By subjecting coated samples to controlled abrasion, manufacturers can evaluate their ability to withstand wear, scratching, or rubbing, ensuring long-lasting protection for metal, wood, or other substrates.

Conclusion: Abrasion testers are essential tools for evaluating the durability and wear resistance of materials and finished products. By subjecting samples to simulated abrasive conditions, manufacturers can assess the material’s performance and make informed decisions about design improvements, material selection, and quality control. Abrasion testing is crucial in industries such as textiles, automotive, flooring, and coatings, ultimately contributing to the development of long-lasting, reliable, and high-quality products.