Evaluating Endurance: The Significance of Perspiration Testers

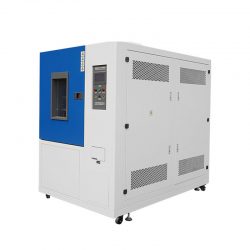

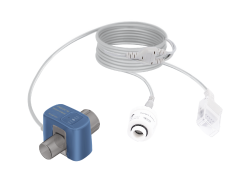

perspiration tester, also known as sweat testers, are essential tools used in the textile industry to assess the durability and colorfastness of fabrics when exposed to perspiration. These testers simulate the effects of human sweat on fabrics, helping manufacturers determine their suitability for garments, sportswear, and other applications. In this article, we will explore the importance of perspiration testers and their practical applications.

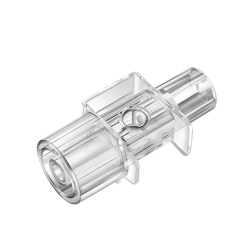

Understanding Perspiration Testers: Perspiration testers are designed to mimic the effects of human sweat on textiles. They create controlled environments where fabrics are exposed to artificial perspiration, allowing manufacturers to assess the fabric’s resistance to color fading, staining, or any adverse reactions when in contact with sweat. These tests help ensure the durability and quality of textiles, providing insights into their performance during active use.

Test Methods: Perspiration testers utilize various methods to simulate sweat and assess its impact on fabrics. Some commonly used test methods include:

pH-controlled sweat: In this method, artificial sweat with a controlled pH level is applied to the fabric specimens. The pH level is typically set to replicate the acidity of human sweat, ensuring realistic test conditions. The fabric samples are then evaluated for any discoloration, staining, or changes in their physical properties.

Salt-based sweat: This method involves the application of salt solutions to fabric specimens to simulate the salt content present in human sweat. The fabric is subjected to the salt-based artificial sweat and subsequently examined for colorfastness, texture changes, or any other undesirable effects caused by salt exposure.

Applications of Perspiration Testers:

Textile and Apparel Industry: Perspiration testers play a vital role in the textile industry to assess the performance of fabrics used in sportswear, underwear, activewear, and other garments that come in contact with sweat. These tests help manufacturers determine the colorfastness, durability, and comfort of fabrics under perspiration conditions. The results aid in selecting suitable materials for specific applications and ensuring customer satisfaction.

Medical and Healthcare Industry: Perspiration testers are also used in the medical and healthcare industry to evaluate fabrics used in hospital gowns, bed linens, or patient clothing. These tests assess the fabric’s ability to withstand repeated exposure to sweat and various washing processes without compromising their performance or quality.

Performance and Athleisure Wear: Perspiration testing is crucial in the development and production of performance and athleisure wear. It ensures that these garments can endure intense physical activities, maintain their appearance, and provide comfort even during prolonged sweating. This testing helps manufacturers create high-quality performance apparel that meets the demands of athletes and fitness enthusiasts.

Quality Control and Standards Compliance: Perspiration testers are used for quality control purposes to ensure that textile products meet specific industry standards and regulatory requirements. These tests help manufacturers validate their products, maintain consistency in production, and ensure that fabrics perform as intended, even under demanding conditions.

Conclusion: Perspiration testers are indispensable tools for evaluating the durability, colorfastness, and performance of fabrics when exposed to sweat. By simulating perspiration, these tests allow manufacturers in the textile industry to assess the suitability of fabrics for various applications, such as sportswear, medical garments, or performance apparel. Perspiration testing aids in material selection, quality control, and compliance with industry standards, ultimately ensuring the production of durable and high-quality textile products.