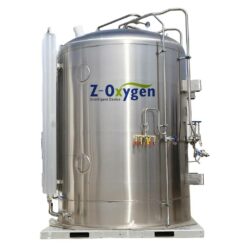

Falling-film Evaporator

The Falling-film Evaporator finds diverse applications in industries like medicine, food, and chemicals. Operating under vacuum, it ensures high evaporation capacity, energy efficiency, and material integrity. It’s integrated into self-reduced membrane evaporators, using gravity and vacuum to circulate solution for efficient evaporation. Its advantages include high heat transfer coefficient, short contact time preventing material degradation, suitability for high-viscosity and foaming solutions, and adaptability to varying conditions.

Falling-film Evaporator Specifications

Designing pressure

0.04Mpa

Designing temperature

130℃

Working temperature

110℃ inlet, 104℃ outlet

working pressure

0.002Mpa

Hydrogen test pressure

0.05Mpa

Volume

21.73m³

Media

strong brine

Main pressure component materials

stainless steel 2205, which needs acid pickling and passivation treatment

Insulation materials/thickness

Aluminum silicate coated metal sheet/100mm

Stainless steel surface undergoes Weight

4282kg

Falling-film Evaporator Applications

The falling-film evaporation device is widely used in water or organic solutions in industries such as medicine, food, chemical industry, light industry and other industries, and can be widely used for waste liquid treatment in the above industries. In particular, it is suitable for thermal material. The device is continuously operated under the low temperature conditions of vacuum. It has high evaporation capacity, energy saving and consumption reduction, low operating costs, and ensuring that the material can not be transformed during evaporation.

The falling-film evaporation device is added to the upper tube box of the heating room of the self-reduced membrane evaporator of the material. After the liquid distribution and the film formation device, it is evenly distributed in the heat exchanges. Under the action of gravity and vacuum induction, Flowing up and down. During the flow, heating and vaporization of the heating medium of the shell, the generated steam and the liquid section enters the separation room of the evaporator. After the steam liquid is fully separated, the steam enters the condenser condensate (single-efficiency operation) or the next effect evaporator is used as the next effect. Heating medium to achieve multi-effect operation, and the liquid phase is discharged from the separation chamber.

Falling-film Evaporator System Characteristics

The solution of the falling-film evaporator is added from the top of the evaporator. The membrane shape is decreased along the tube wall under the action of gravity, and the evaporation will be thickened during this process, and the concentrated solution is obtained at the bottom. The falling-film evaporator can evaporate the solution of concentration and large viscosity.

Because the solution flows in a membrane in a one-way evaporator, the heat transfer coefficient is high.

The stay time is short, which is not easy to cause the material deterioration, and it is suitable for treating thermal material.

The solution retention is small, and the falling-film evaporator can take fast operation based on changes in energy supply, authenticity, feeding amount, concentration, etc. Nearly,

Since the process, the solution is only flowing under the action of gravity, not by the high temperature difference, it can be evaporated by low temperature differences.

The falling-film evaporator is suitable for the evaporation of foaming materials. Because the solution evaporates in the inner membrane of the heating pipe, it is separated from the bottom. Some material solution are separated from all the secondary steam into the separation. The whole process of the material has not been formed too much impact, which avoids the formation of foam.

https://www.cstitanium.com/products/falling-film-evaporator.html