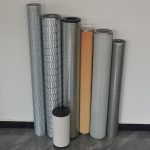

FILTER ELEMENTS & FILTER CARTRIDGE FOR SALE

FILTER ELEMENTS & FILTER CARTRIDGE FOR SALE

The filter element can purify the polluted media, and achieve the cleanliness required by our production and life, with a certain degree of cleanliness. Filters are widely used, ranging from industrial products such as iron and steel smelting, electric power production, and ocean purification, etc. to domestic drinking water treatment, domestic garbage utilization, automobile burning filtration, bicycle lubricating oil filtration, etc. Therefore, cartridge filter elements are used in clean technologies in our lives. The hydraulic system is divided into an oil suction filter, pipeline filter, and oil return filter.

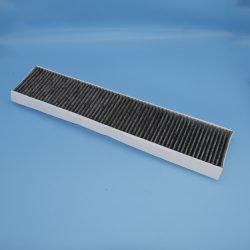

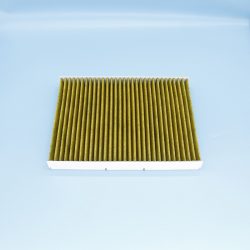

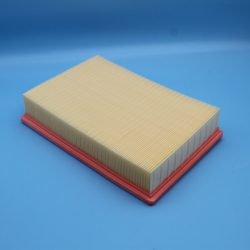

Filter Element Characteristics

The filter element is made of American fiber filter material with strong hydrophobicity and oleophobicity, and the framework with good permeability and high strength is adopted to reduce the resistance caused by passing.

The filter core adopts a German fine-perforated sponge, which can effectively prevent oil and water from being carried away by high-speed airflow so that the small oil droplets passing by gather at the lower end of the filter core sponge and are discharged to the bottom of the filter container.

A reliable sealing ring is adopted at the junction of the filter element and the filter shell to ensure that the air flow is not short-circuited and prevent impurities from directly entering the downstream without passing through the filter element.

Anti-corrosion reinforced nylon end cover and anti-corrosion filter core framework are adopted for filter core, which can be used in severe working conditions.

Typical Applications of Filtration Elements

Electronic industry: pre-filtration of the reverse osmosis water system and pre-filtration of the deionized water system.

Food industry: filtration of beverages, beer, mineral water, etc.

Chemical industry: filtration of organic solvents, inks, etc.

Pharmaceutical industry: filtration of pharmaceutical, biological and plasma products, compressed air, and gas filtration.

Others: electroplating solution, metal cutting fluid, photosensitive resist and filtration of magnetic media, etc.