Fusion Casting Category

Self-cleaning screens are a special type of screening media made of multiple individual wires or polyurethane material. Independent vibrations of the wires are generated at variable frequencies to provide a good self-shielding effect without clogging the mesh. Self-cleaning screens offer less clogging, longer wear life and higher screen efficiency than conventional screens. Due to these features, Self-cleaning screens are becoming more and more popular among customers in many industries.

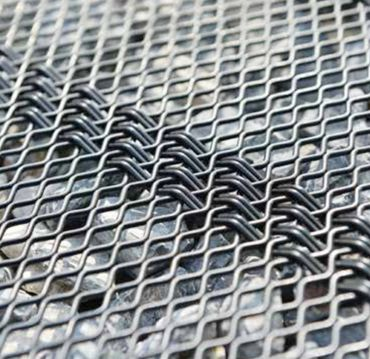

RD-1 self-cleaning screen: The per-undulated wire, placed one next to the other from the aperture. this way the materials follow the direction of one of the diagonals of the aperture. as the wires are independent, the collisions produced by the products cause the differences in the vibration that prevent the clogging of the fine products between the wires. Read more.

RD-2 self-cleaning screen: Another type of anticlogging meshes that keeps the same properties but adds a straight wire that avoids their abnormal separation in case of particulate wedging. This allows a very precise classification. Read more.