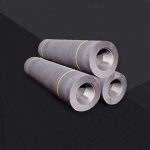

Graphite Crucible

The main raw material of carbon graphite crucible is crystalline natural graphite. Therefore, it maintains the original physical and chemical properties of natural graphite. That is: it has good thermal conductivity and high-temperature resistance. In the process of high-temperature use, the coefficient of thermal expansion is small, and it has certain strain resistance to rapid heating and rapid cooling. It has strong corrosion resistance to acid and alkaline solutions and excellent chemical stability. There are many types and specifications of the graphite casting crucible, which are not limited by the production scale, batch size, and the variety of melting material. It can be selected at will, and has strong applicability, and can ensure the purity of melting material.

Application of Graphite Crucible

Graphite crucible has obvious characteristics and is widely used. The graphite crucible for fire heating is mainly used for smelting copper, aluminum, alloy and other non-ferrous metals. Due to the reasonable design, advanced structure, novel material and low energy consumption compared with the same type of furnace, graphite crucible has been used in many fields, using clean energy such as natural gas or liquefied gas as fuel with less pollution. Resistance furnace high purity graphite crucible is mainly used for melting gold, silver and rare metals.

The graphite crucible has a small coefficient of thermal expansion. It has a strong resistance to strain for both extremely hot and extremely cold. It is resistant to strong acid and alkali, and can be used for heating a variety of liquids; In addition to chemistry, graphite crucible is widely used in metallurgy, casting, machinery, chemical industry and other departments; Graphite crucible is made of natural graphite, which keeps the original excellent characteristics of graphite. It is used to make heating element and heat shield of vacuum furnace, and also used to make structural parts such as bracket, material tray, guide rail, bolt, bearing, fan blade and so on. The application of graphite crucible in vacuum furnace greatly simplifies the design and manufacture of vacuum furnace, reduces the consumption of metals such as tungsten, molybdenum, tantalum and stainless steel, reduces the cost, improves some properties of vacuum furnace and expands the application scope of vacuum furnace.

Graphite Crucible Uses

Put it in a dry place after use, and avoid rainwater intrusion; Bake slowly to 500 ℃ before use.

According to the capacity of the carbon graphite crucible, do not squeeze too tightly, so as to avoid the metal thermal expansion cracking the crucible.

When taking out the molten metal, scoop it out with a spoon, and useless calipers as far as possible. If calipers and other tools are used, they should be consistent with the shape of the crucible, so as to avoid local excessive stress and shorten the service life.

The service life of the graphite casting crucible is related to its usage. It should be avoided that the strong oxidation flame is sprayed directly on the crucible, which shortens the service life of the raw material.