High Hardness TPEs

Product description: high-hardness (≥90A) TPU materials, with problems of abnormal glue, surface scratches, uneven bright fog, surface tingling, particles, etc, which are caused by excessive crystallization speed in the process of pipeline extrusion.While ATP’s new series TPU can Effectively solve those problems.

Applicable: all kinds of TPU cables and casings with a hardness requirement of more than 90A for the sheath

Product features:

1. In the case of high hardness (90A-98A), it still has very appropriate melt fluidity and crystallization speed, which solves the common problems of high hardness TPU materials in the pipeline extrusion process: abnormal glue, surface Scratches, uneven fog, surface numbness, particles, and other poor quality;

2. Excellent mechanical properties and elasticity; glossy and matte materials are available;

3. Processing characteristics: The production efficiency of 60-100 meters per minute can be achieved by using the same PVC screw machine.

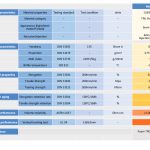

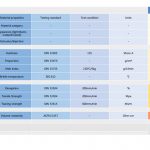

Technical Data of High Hardness TPEs

Technical Data Sheet

Model

Material Properties

Test Standard

Test Condition

Unit

2898F-ESS-1183S

General Characteristics

Material Category

–

–

–

Appearance(Light/Semi-matte/Frosted)

–

–

–

Extrusion/Injection

–

–

–

Physical Characteristics

Hardness

ISO 48

15S

Shore A

98

Proportion

ISO 1183

–

g/cm³

0.898

Melt Index

ISO 1133-1:2011

190℃/2.16kg

g/10min

9.1

Brittle Temperature

ISO 812

–

℃

Mechanical Properties

Elongation

ISO37:2017

200mm/min

%

217

Tensile Strength

ISO37:2017

200mm/min

Mpa

37.229

Tearing Strength

ISO34-1:2015

500mm/min

KN/m

Hot Air Aging

Elongation Retention Rate

ISO37:2017

–

%

Tensile Strength Retention Rate

ISO37:2017

–

%

Electrical Performance

Volume Resistivity

ASTM D257

–

Ohm-cm

Permittivity

ASTM D150

–

–

Combustion Performance

Vertical Burning Test

UL 94

3.0/6.0mm

–

Oxygen Index

ASTM D2863

–

%

Feature