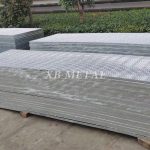

hot-dip galvanized steel grating For Drainage Covers

hot-dip galvanized steel grating For Drainage Covers

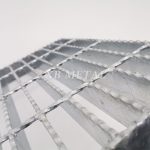

The steel grating adopts the world-class equipment from the Italian company ORSOGRIL. The flat steel and the twisted square steel are distributed at certain intervals. The computer-controlled high-voltage resistance welding presses the twisted square steel into the flat steel to obtain a firm welding joint. The board surface is flat and contains steel grating with extremely high strength.

Parameter

Data

Bear Bar Type

Flat Bar, I-Bar, Serrated Bar, etc

Bearing Bar Size

20x5mm, 30x3mm, 30x5mm, 40x3mm, 40x5mm, 50x5mm, etc

Bearing Bar Spacing

30mm, 33mm, 40mm, 50mm or other size

Cross Bar Type

Twisted steel bar, Flat bar

Cross Bar Size

6mm, 8mm or other

Cross Bar Spacing

50mm or 100mm

Weld Way

Welded , Pressure-locked , Swage Locked

Material Grade

Mild Steel(Q235B), Stainless Steel 304 or 316, etc

Surface treatment

Hot dipped Galvanized, Spray paint or other

Standards

Steel Grating Standard

Steel Material Standard

HDG Coating Standard

China

YB/T4001-2007

GB700-88

GB/T13912-92

USA

ANSI/NAAMM(MBG531-88)

ASTM-A36

ASTM-A123

UK

BS4592-1987

BS4360(43A)

BS729

Australia

ASl 657-1992

AS3679

ASl650

The bearing flat steel standard of steel grating should be selected according to the practical bearing requirements. Commonly used standards are: 25x3mm, 25x4mm, 25x5mm, 30x3mm, 30x4mm, 30x5mm, 32x3mm, 32 x5mm, 35x3mm, 35x5mm, 40x3mm, 40x4mm, 40x5mm, 50x3mm 50x5mm, 60x5mm, 65x5mm, etc. It can also be customized according to customer requirements.

PRODUCT FEATURES

Steel grating is made by welding with flat steel and bars with certain distances.It goes through cutting, opening, edging and other processes. The products enjoy the features of high strength, light structure, high bearing, convenience for loading and other properties.The hot dipped zinc coating gives the product excellent anti-corrosion resistance.