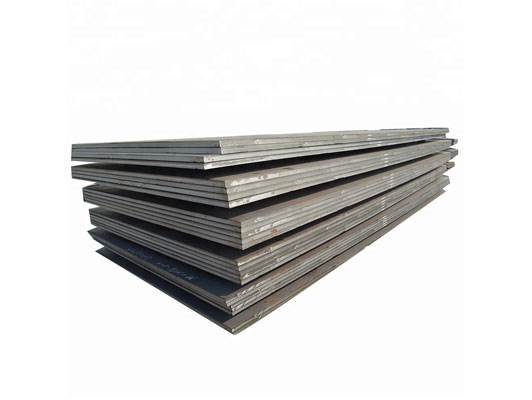

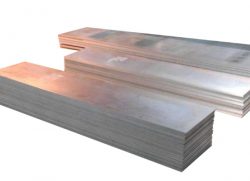

Hot Rolled Steel Plate

Main Feature of Hot Rolled Steel Plate

Hot steel coils production is a rolling procedure that relates rolling steel at a high temperature (usually above 1700°F) and over the recrystallization temperature of steel. When the steel heating temperature is higher than the recrystallization temperature, it can be formed and shaped easily, and the steel can be made to larger sizes. Hot rolled steel is usually cheaper than cold rolled steel because of the fact that it is usually manufactured without any delays and then does not require reheating of the steel (as with cold rolling). As steel cools, it contracts slightly compared to cold rolling, so there is less control over the size and shape of the finished product. Hot Rolled Steel Plate is a piece of flattened hot rolled steel that is thicker than 1/4 inch (0.250mm). It has many applications in the manufacturing, industrial and construction industries where it is used structurally (not aesthetically). Hot Rolled Steel Plate is measured by its thickness in inches. Huaruo has long been devoted to producing prime hot rolled steel plates. It would be a nice option for you to have a try.

Hot Rolled Steel Plate Production Process

The hot rolled steel plate as known as HRP. This main produce semi-finished material is steel slab with a certain thickness and width. The slabs are heated in a natural gas-fired furnace before processing it through a hot rolling mill. This process reduces the thickness of the standard figures.

Specific Uses and Applications of Hot Rolled Steel Plate

Typical uses of hot rolled steel plate involve general fabrication, structural members, high-rise buildings, bridges, storage tanks, and mixers

HUARO hot rolled steel plate is ideal for the following applications:

l General structural articles

l Sports stadiums

l Buildings and skyscrapers

l Bridges and other foundations

l Reinforcing requirements

l Various heavy machinery, earthmovers, and bulldozers