Hydraulic Guillotine Shearing Machine

Details of Hydraulic Guillotine Shearing Machine

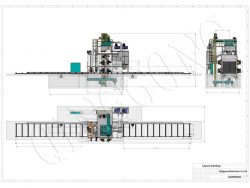

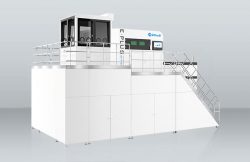

CNC hydraulic guillotine shearing machine is a frequently used shearing machine in the metal processing industry. Due to its outstanding productivity and low noise, it is increasingly used by metal fabricating industries. In addition, the CNC system ensures easy operation and adjustment.

Guillotine shearing machines can be divided into different types according to different drive methods. Hydraulic guillotine shear is the most popular shear for its high productivity, excellent capacity and cutting quality.

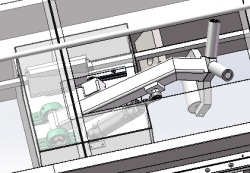

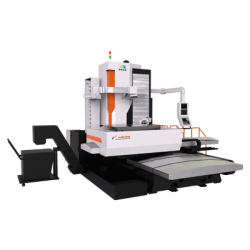

The Guillotine Shearing machine adopts a ball screw, linear guide and an electric motor to drive the back gauge with high positioning accuracy

Integrated steel welded structure, eliminate stress by vibration, with good rigidity

Adopt the advanced hydraulic integrated valve block which is in compact structure and will reduce piping connections, and improves system reliability and maintainability

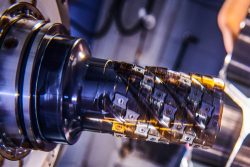

Optional MD11 system Estun E200PS, DELEM DAC310s and DELEM DAC360s, Cybelec CT8 CNC controller

Serials connection of oil cylinder to prevent the cutting angle changing during the operation of the shearing machine

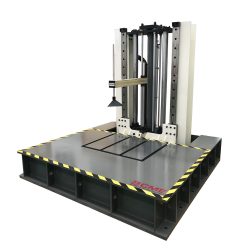

Accumulator return smooth and rapid

Optional Manual/automatic adjustment of blade clearance (depend on the controller), accurate, rapid and convenient

Adjustable shear angle to reduce sheet distortion

Motorized back gauge and position display make it convenient and precise

Rolling material support ball will reduce the scratch and frictions as well