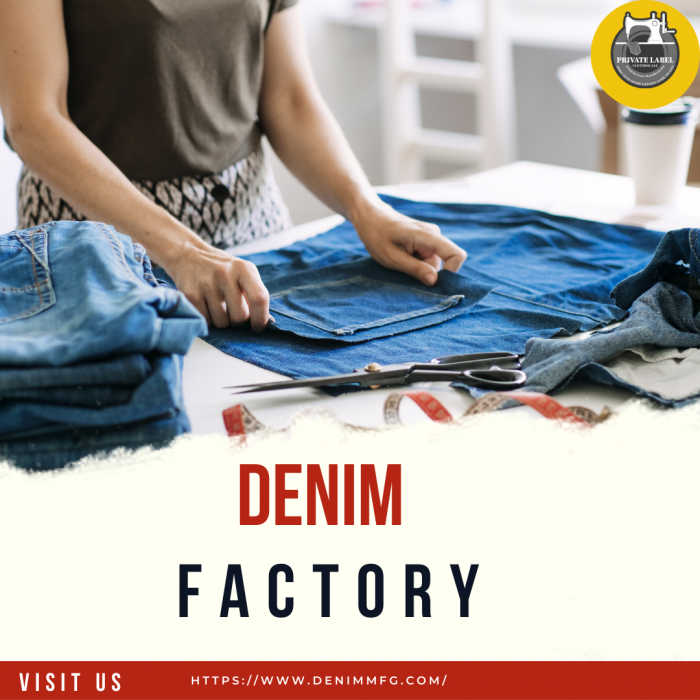

Inside the Denim Industry: Exploring the Essence of Denim Factories

Discover denim’s classic style and innovative craftsmanship. Denim factories are the heart of the denim industry, turning raw materials into our favorite jeans. This blog post will take you on a captivating tour of denim manufacturers, from their history to their present methods.

The Birth of Denim: Unveiling the Heritage of Denim Factories

Denim originated in the 19th century, when strong workwear was in demand. Denim mills became creative hubs where skilled artisans handcrafted each pair of pants. These factories powered the denim industry, making culturally significant clothes.

Initially, denim production was labor-intensive. Workers carefully used ancient technology to spin cotton into strands and weave fabric. Each step needed generations-honed skill.

Denim factories changed with fashion and technology. Innovative methods were used to speed production while preserving denim authenticity. From automated looms to computerized cutting machines, technology has improved productivity without sacrificing quality.

Despite all the changes, these sacred rooms’ enthusiasm for workmanship persists. Denim mills thrive on years of tradition and innovation.

Every stitch in denim manufacturing carries a rich history. Factory workers’ passion and talent keep this classic cloth in our wardrobes year after year.

Factory Chronicles: The Making of Denim from Raw Material to Finished Product

The denim factory is a creative and skilled place where raw materials become our favorite fabric. Every step requires accuracy, talent, and detail.

The first step is choosing high-quality cotton fibers. These fibers are spun and dyed to make yarns with distinct textures and hues. Denim is made by weaving threads on specific looms.

After preparation, the fabric is treated to give it its particular qualities. For shrinkage prevention, mercerizing for strength and shine, and enzyme wash for fading effects. Chemical and machinery expertise is needed for each treatment.

After painstakingly laying out patterns on numerous layers of denim fabric, they are chopped into pieces. Precision is needed to assure size and shape consistency across thousands of jeans. After cutting, expert seamstresses use specialized sewing machines to carefully join these parts together. They pay attention to straight seams, reinforced pockets, robust zippers, and buttons—everything that makes a good pair of jeans.

Before being packaged for worldwide distribution, each item is meticulously inspected for flaws. This guarantees that only the best pairings reach store shelves.

Denim manufacture requires skilled artisans who take delight in their job from inception to end. Their dedication to turning raw materials into classic pieces that become part of our wardrobes shows.

Innovation at Work: Technology and Techniques in Modern Denim Factories

From humble origins, denim production has grown. Modern denim factories use cutting-edge technology and methods to make attractive, durable pants.

Automation is a major improvement in denim manufacturers. Precision and efficiency allow these devices to boost output and save manufacturing time. Automation has transformed manufacturing from cloth cutting to stitching.

Modern denim companies use automation and new dyeing methods to produce a variety of colors and finishes. Traditionally, blue jeans were dyed indigo. With advances in technology, companies may now use several dyes and pigments to create distinct washes and effects.

From developing patterns digitally using CAD software to prototyping clothes using 3D printing before mass production, today’s denim factories are innovative.

As we explore this fascinating world where tradition meets technology, we see that modern denim factories are pushing the limits of innovation, advancing an industry rooted in heritage while embracing advancement like never before!

Sustainability in Focus: Eco-Friendly Practices in Denim Manufacturing

From excessive water and energy consumption to hefty dyeing chemicals, the denim industry has long been environmentally problematic. Today, denim companies use eco-friendly methods to lessen their environmental impact.

Water conservation is crucial to denim production sustainability. For washing and finishing, traditional denim manufacture uses a lot of water. Innovative factories use laser fading and ozone treatments to save water consumption and retain a high-quality finish.

Responsible manufacturers use eco-friendly dyeing methods that eliminate hazardous azo dyes and heavy metals in indigo dye baths to reduce chemical contamination. Instead, they use plant or bacteria-based replacements without sacrificing color brightness or endurance.

To properly dispose of remaining contaminants before releasing them into nature, many sustainable denim factories use wastewater treatment systems. This pledge preserves clean water for local communities and protects ecosystems.

Modern denim factories are improving sustainability without losing quality or style by using these eco-friendly supply chain techniques. It’s encouraging to see how this business is adjusting to improve fashion and the earth as consumers become more environmentally conscious and want greener products.

Denim Factory Workers: The Artisans Behind Every Pair of Jeans As we learn more about denim manufacturers, we can’t overlook the laborers who make our jeans. Their generations-old knowledge and experience ensure that each pair of jeans is made with accuracy and care.

From pattern cutters to sewing machine operators, every stage in manufacturing involves knowledge that machines cannot copy. These motivated workers work hard to make high-quality denim goods that satisfy consumers worldwide.

Their dedication extends beyond operating technology; they are artists who comprehend the complexities of denim masterpieces. These experienced artisans put their hearts into each pair of jeans, from choosing raw fabrics to stitching delicate details.

Working behind the scenes, these unsung heroes help preserve the denim industry. Their passion for their craft shows in every stitch, helping preserve denim manufacturing’s spirit and craftsmanship. Consumers should respect their contributions. Supporting firms that value fair salaries, safe working conditions, and employee well-being can help these bright people succeed in their careers.

For More Info:-https://www.denimmfg.com/