Intalox Metal Tower Packing

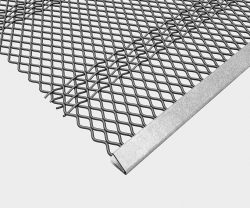

Metal Protruded Corrugated Sheet Packing is perforated 70 very small holes with thorn per square centimeter, then is pushed to corrugated sheet, finally it is assembled to the coil. Because the wetting ability increases, it still has the excellent separation performance of wire gauze packing when liquid flow is large.

Parameters Of Intalox Metal Tower Packing

Type

specifific surface are m2/m3

Void Volume

%

Heaping Weight

Kg/m3

Wave

Height

mm

Theoretical platenumberm-1

Δ PPa/m

Max.F-factor

m/s(kg/m3)0.5

250Y

250

97

85-100

12.5

2.5-3.0

300

2.6

500Y

500

93

170-200

6.3

3.0-4.0

200

2.1

700Y

700

85

240-280

4.5

5.0-7.0

900

1.6

Advantages of Intalox Metal Tower Packing

Low pressure drop and high efficiency

Large effective interfacial area

High mechanical strength

Low cost

Application of Intalox Metal Tower Packing

Transfer towers both small and large diameter

Deep vacuum towers where low pressure drop is crucial

Distillation, absorption etc

High pressure towers where capacity significantly exceeds conventional trays