Lead Screw

VXO precision lead screws are an excellent economical solution for your linear motion requirements. For more than 15 years, VXO has designed and manufactured the highest quality lead screw assemblies in the industry. Our precision lead screw ensure accurate positioning and product lead time is 7-15 days. We also produce Trapezoidal thread, Unified screw thread, ACME screw thread, special Pitch, and multiple start thread. Nut configuration is not restricted and it is possible to manufacture in accordance with customer’s design.

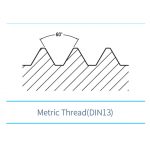

Types of Lead Screw

No other linear motion component combines the speed, accuracy, efficiency, repeatability, quiet operation, lubrication retention, load capacity, and compactness of VXO lead screws. Our lead nuts are available in a standard threaded or flanged mounting configuration, and anti-backlash nuts provide the best positional repeatability.

Advantages Of Using Lead Screws

Lead screws have many advantages – some of these are;

High load-carrying capacity

Compact

Easy to design into a system

Minimal number of parts

Smooth operation

Quiet

Require little maintenance

Where Is A Lead Screw Used In Real Life?

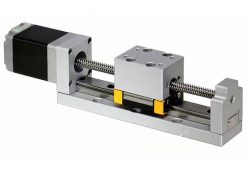

Lead screws are often used in linear actuators, machine tools, screw jacks, presses and vises.

Lead screws are also found in biomedical environments such as clinics and hospitals. For example, lead screws are used in pumps for blood and drugs requiring precise fluid measurement and fluid delivery. They are also used in lab testing equipment such as devices that sample, scan and handle fluid.

Other popular industries in which lead screws are used include defense, transport and industrial automation.

What Is The Difference Between A Lead Screw And A Ball Screw?

Ball screws and lead screws can sometimes be used in the same applications. Typically, ball screws are used in industry applications that need a lot of load or life while lead screws are used in smaller, lighter duty applications. Lead screws however are highly customizable with the ability to interchange leads, sizes, nut configurations quickly. Cost is usually not the primary consideration when selecting a screw technology.