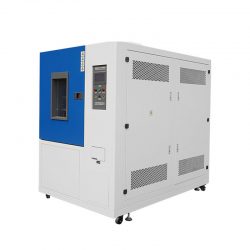

Measuring Surface Friction: The Role of Coefficient of Friction Testers

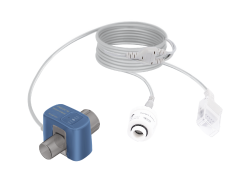

coefficient of friction tester, also known as friction testers, are valuable tools used in various industries to measure the level of friction between two surfaces. These testers provide quantitative data about the interaction between surfaces, helping manufacturers assess slip resistance, product performance, and safety. In this article, we will explore the significance of coefficient of friction testers and their practical applications.

Understanding Coefficient of Friction Testers: Coefficient of friction testers are designed to measure the frictional forces between two surfaces in contact. They utilize controlled methods to determine the static and kinetic coefficient of friction, indicating the resistance to relative motion. This data is crucial for understanding the traction, grip, or slippery tendencies of materials and products, aiding manufacturers in improving safety, quality, and performance.

Test Methods: Coefficient of friction testers employ different methods to measure friction, depending on the specific industry or application. Some commonly used test methods include:

Inclined Plane Test: In this test, a sample is placed on an inclined plane, and the angle of the slope is gradually increased until the sample starts to slide. By measuring the angle at which sliding occurs, the static coefficient of friction can be calculated. This test helps assess the resistance to movement on inclined or sloped surfaces.

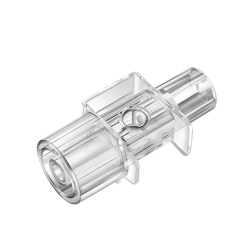

Dragging Friction Test: This test involves pulling a sled, weighted or unweighted, across a surface to measure the resistance. The force required to initiate and sustain sliding is measured, allowing the calculation of static and kinetic coefficients of friction. This test is helpful in evaluating the grip and traction of materials used in flooring, footwear, or other applications where surface contact is important.

Belt Friction Test: This test simulates the movement between surfaces, such as conveyer belts, by rubbing them against each other. The force required to maintain the sliding motion is measured, providing data on the kinetic coefficient of friction. This test is commonly used in industries involving conveyer systems and material handling.

Applications of Coefficient of Friction Testers:

Flooring and Safety Industry: Coefficient of friction testers play a crucial role in evaluating the slip resistance of flooring materials, such as tiles, carpets, or non-slip coatings. These tests ensure that surfaces meet safety standards and provide adequate traction to prevent accidents in areas prone to wet or slippery conditions, such as hospitals, restaurants, or swimming pool areas.

Packaging Industry: Coefficient of friction testers are employed to assess the friction characteristics of packaging materials, such as films or papers. The data helps determine the ease of material handling during packaging operations, prevent excessive slipping or sticking on automated systems, and ensure the efficiency of packaging processes.

Footwear Industry: Coefficient of friction testing is essential in the footwear industry to evaluate the slip resistance of shoe soles or outsoles. It helps manufacturers measure the grip and traction of footwear on different surfaces, ensuring the safety and stability of the users.

Automotive Industry: Coefficient of friction testers are utilized in the automotive industry to test the frictional characteristics of vehicle components such as brake pads, tires, or clutch materials. These tests help determine the optimal materials for good braking performance, tire grip, and overall driving safety.

Conclusion: Coefficient of friction testers provide quantitative data about the frictional characteristics of surfaces, helping manufacturers evaluate slip resistance, product performance, and safety. With applications in flooring, packaging, footwear, automotive, and various industries, these testers aid in optimizing product design, ensuring regulatory compliance, and improving user safety. By measuring the coefficient of friction, manufacturers can make informed decisions regarding material selection, surface treatments, and quality control, ultimately enhancing the reliability and performance of their products.