Metal Injection Molding

Metal injection molding(MIM). MIM combines the shaping capability of plastic injection molding and the material flexibility of the conventional powder metallurgy to offer cost-effective solutions for highly complex part geometries.

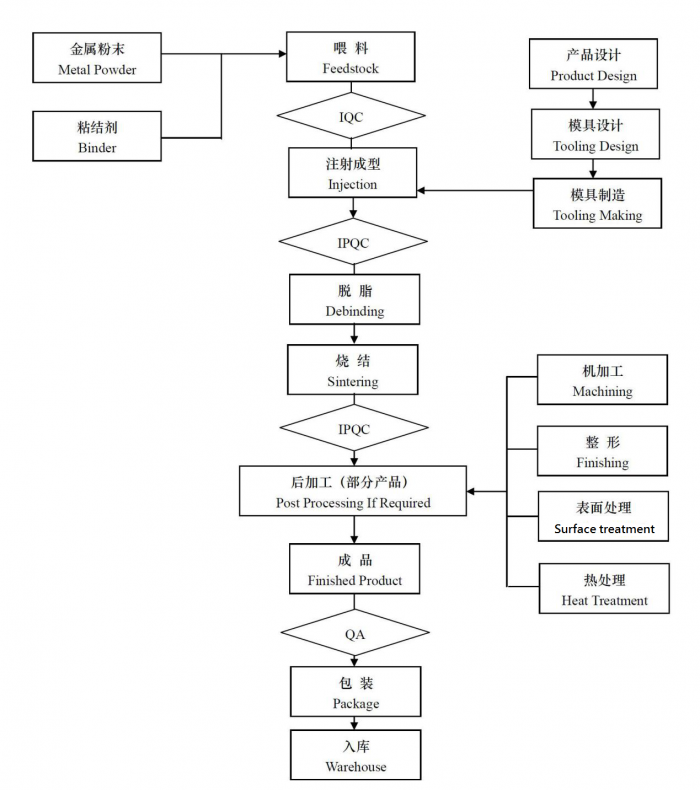

MIM process

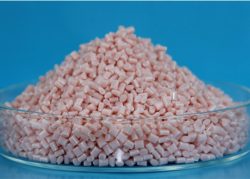

Step 1: Feedstock

Very fine metal powders are combined with thermoplastic and wax binders in a precise recipe. A proprietary compounding process creates a homogenous pelletized feedstock that can be injection molded just like plastic. This achieves ultra-high density and close tolerances over high-production runs.

Unlike standard powder metallurgy, which can achieve only 80-90% of theoretical density, MIM results in 95-100%. This means we can achieve close tolerances and reduce costs by producing small, complex parts over high production runs.

Step 2: Molding

The feedstock is heated and injected into a mold cavity under high pressure. This enables us to produce extremely complex shapes and allows for shorter cycle times.

Once molded, the component is referred to as a “green” part. Its geometry is identical to the finished piece but is about 20% larger to allow for shrinkage during the final sintering phase.

Step 3: Debinding

Binder removal (debinding) involves a controlled process to remove most of the binders and prepare the part for the final step – sintering.

Once debinding is complete, the component is referred to as brown.

Step 4: Sintering

The brown part is held together by a small amount of the binder and is very fragile.

Sintering eliminates the remaining binder and gives the part its final geometry and strength.

During sintering, the part is subjected to temperatures near the melting point of the material

MIM Product Features

The sintered products not only have the same complex shape and high precision as the products produced by plastic injection molding but also have the same physical, chemical, and mechanical properties as the forgings. In traditional machining technology, for complex parts, is usually to decompose and make a single part, and then assemble; After using PIM technology, it can be considered to integrate it into a complete single part, which greatly reduces the production steps, simplifies the processing procedures, saves costs and improves efficiency.

MIM Technology Advantages

MIM technology not only has the advantage featured by less process as conventional powder metallurgy, such as low density, uneven material, low mechanical properties, difficult to form thin wall and complex structure. It is especially suitable for mass production of small, complex, and special metal parts.