Molybdenum Rod

HSG molybdenum bar supplier provides the pure molybdenum bar for sale with molybdenum content greater than 99.95%.

Also, as a molybdenum rod supplier, we offer high temperature molybdenum rod (lanthanum molybdenum alloy rod) which contain lanthanum 0.4~1.2%, molybdenum content in addition to impurities.

TZM molybdenum rod :0.4~0.6Ti, 0.07~0.12Zr, 0.01~0.05C.

Specification of Molybdenum Rod

Fe

Ni

C

Al

O

N

0.004

0.002

0.0028

0.0005

0.005

0.002

Si

Ca

Mg

Cd

Sb

Sn

0.0013

< 0.001

< 0.0005

< 0.001

< 0.0005

< 0.0005

P

Cu

Pb

Bi

Mo

< 0.001

< 0.0005

< 0.0005

< 0.0005

>99.95%

Diameterial(mm)

Dia Tolerance(mm)

Lenght(mm)

L Tolerance(mm)

16-20

1

300-1500

2

20-30

1.5

250-1500

2

30-45

1.5

200-1500

3

45-60

2

250-1300

3

60-100

2.5

250-800

3

Application of Molybdenum Rod

Used for manufacturing electric vacuum devices and electric light source parts

Suitable for processing ion implantation parts

The molybdenum products can be used as high temperature heating body and high temperature structural parts

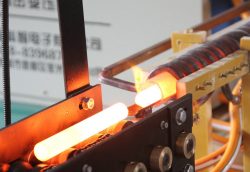

In the glass and refractory fiber industry used as furnace electrode, working in 1300℃ glass molten liquid, long life

Used as electrodes in rare earth industry

Features of Molybdenum Rod

01.

Good corrosion resistance (The surface of molybdenum rod is easy to produce a layer of dense natural protective film, It can be well to protect the matrix from corrosion by artificial anodic oxidation and coloring, good casting performance can be cast aluminum alloy or processing Plastic deformation of good aluminum alloy.)

02.

High strength (molybdenum rod have the high strength.After a certain degree of cold processing can strengthen the matrix strength, some grades of molybdenum rod can also be enhanced by heat treatment).

03.

Good thermal conductivity (The conductive thermal conductivity of molybdenum only less than the silver, copper and gold).

04.

Easy processing (After add some certain alloying elements, you can get a good casting performance of aluminum alloy casting or processing plastic deformation of aluminum alloy).