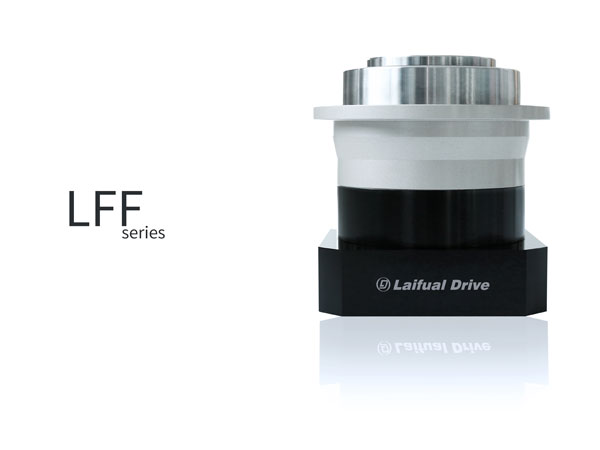

Planetary Gearbox

Planetary gearboxes can be powered by either electric motors, hydraulic motors, or petrol or diesel combustion engines. The load from the sun gear in transmission is distributed to several sun planet gears which can either be used to drive an outer ring or a shaft or spindle. The central sun gear takes a high-speed, low-torque input. It drives several rotating external gears which increases the torque. The simple design is a highly efficient and effective way of transferring power from a motor to an output. Approximately 97% of the energy input is delivered as an output.

Planetary Gearbox Applications

In addition to being used in vehicle transmissions, planetary gearboxes are also used in different applications in various industries. They provide high precision and high torque-to-volume ratio, making them ideal for applications such as increasing torque, reducing speed, precise positioning and controlling replicable machinery. Applications include:

AGV

Wheel drive

Slewing drive

Winch drive

Slewing drive

Track drive

mixing

Pump

Cutter head

renewable energy

Medical scanner

Operating table

Petrochemical

How to Select Planetary Gearbox

Gear ratio

Gear ratio can also be defined as the correlation between the number of teeth of two different gears. Generally, the number of teeth of a gear is proportional to its circumference. This means that a gear with a larger circumference will have more gear teeth. Therefore, the relationship between the circumference of the two gears can also give an accurate transmission ratio.

Speed

The speed is proportional to the gear ratio of the system. If the input gear has more teeth than the output gear, the speed of the output shaft will increase. On the other hand, if the number of teeth of the output gear is greater than the number of teeth of the input gear, the opposite situation will cause the output shaft speed to drop. Generally, the output speed can be determined by dividing the input speed by the gear ratio. The higher the ratio, the lower the output speed, and vice versa.

Output torque

When selecting a planetary gearbox, the output torque is an important parameter. Gear reduction will reduce the relatively high speed of the motor and provide a lower speed at the output.

Peak overload torque

The peak overload torque is a short-term overload of the allowable output torque.

Rebound

Backlash refers to the angle at which the output shaft of the gearbox can rotate without the input shaft moving or there is no gap between the teeth of two adjacent gears. For applications that do not involve load reversal, there is no need to consider gaps. If the motion cycle is completely repeated, the backlash of the planetary gearbox theoretically has no effect on the repeatability. However, in precision applications with reverse loads such as robotics, automation, and CNC machine tools, clearance is critical to accuracy and positioning.

![GlucoCare Review-[#USA Scientifically Proven] 100% Natural Support GlucoCare Supplement!](https://salesale.sale/btabcloud/uploads/2023/07/gcbseditable-168873130784clp-250x94.png)