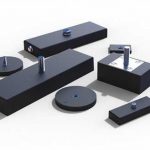

Pot Magnets

Knowledge of Pot Magnets

Pot magnets or cup magnets are named after their shape and they both refer to the same group of magnetic products. By gluing a round shape magnet into a steel pot/cup you get a prototype pot magnet. The structure of pot magnet forms a special magnetic circuit to concentrate magnetic field on working side to get much stronger holding force than a single magnet. The steel housing also protects brittle magnet materials typically NdFeB and Ferrite from breaking easily.

Pot magnet usually is a metal shell with a magnet, sometimes has filler between them. The magnet could be NdFeb, Ferrite, Alnico, and Smco. After placed in the metal shell, the pot magnet could possess a strong pull strength and excellent field projection ability when contact with the workpiece directly.

What is a Pot Magnet?

A pot magnet is a permanent magnet encased in a steel shell. Which is sometimes called a pot, hence the name ‘pot’ magnet. A permanent magnet emits a magnetic field without the need for any electricity. Pot magnets are often used as magnetic bases and magnetic holders for large supermarket ceiling signs.

Pot magnet refers to a group of Magnetic Assemblies that uses a metal pot to realize Magnetic Circuit design. So that magnetic energy is mostly concentrated on the edge of the metal pot to create strong holding force on this side.

These simple-looking screw in magnets are carefully designed following the physical practice of utilizing magnetic field strength. By conducting the magnetic field strength via the steel pot. An alternating-pole-pattern of; “S-N-S” or “N-S-N” is made on the holding surface of the pot magnet. As a result, it generates even higher holding force than using just magnet without steel pot.

With this principal design, The rare earth pot magnets come in various sizes and basically bigger size means higher holding force.

Screw holes, countersunk holes, through holes, etc are made on pot magnets to make it easier for mounting jobs. Accessories such as thread bush and clips are added so that pot magnets can be used in even more working situations.

The neodymium in these pot magnets could have a higher working temperature and intrinsic coercivity. The neodymium iron boron pot magnet can even be used as a Class I or Class II food grade device. The Pot Magnets With Hooks made of neodymium iron boron have the characteristics of small size and large holding force. When they are attached vertically on the surface of the object, the strength can be maximized. In addition to the built-in magnet and the external iron shell structure, its total pull strength also depends on the material, thickness, flatness, and friction of the surface to be attached.

Variant of Cup Magnets

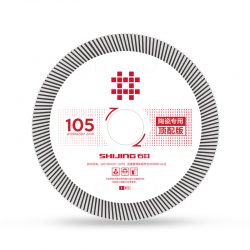

The NdFeb Magnet is much more expensive and produces even stronger force of the same size. The Ferrite version is a good choice when a user has a low budget. NdFeB pot magnet goes to working condition that requires high safety margin.

Based on the prototype pot magnet many variant magnetic products are made by adding mounting holes, threads, hooks, or other fasteners to meet different holding applications. They are then called Pot Magnet With Mounting Hole, Pot Magnet With Threads, Flat Pot Magnet, Pot Magnet With Cable Holder, Deep Pot Magnet, Magnetic Ceiling Hooks, etc. Some of them could look so different from the prototype pot magnet but as far as their core working principle does not change, we still call them “pot magnet”.

We coat rare earth pot magnets with zinc/galvanized, nickel, white or other colors powder painted, can also provide custom coatings to meet your environmental requirements.

Applications of Pot Magnets

Neodymium pot magnets are widely used in industry and our daily life, such as in workshops, factories, warehouses, and offices. It can also be used to make labels, posters, tools, Christmas wreaths, notes, etc.

When you want to hold something or fix something either permanently or temporarily like label, poster, tools, Christmas wreath, lights, etc.

More importantly, if you want to do it with ease, then you might want to choose from our wide selection of pot magnets. Pot magnets from WZ Magnetics Co., Ltd, the Pot Magnet Manufacturer and pot magnet supplier, come in different sizes, forces, and are mounted with different accessories to meet the application request as much as possible.

How to Choose the Most Suitable Pot Magnet for Your Applications1. Holding Force

The Priority for consideration goes to holding force – The one matches the weight of the object you are about to hold.

2. Safety Concern

If you are about to hold a heavy object, An extra 10% safe margin Required. The higher the safer as long as it is within the budget.

3. Strength of threaded neodymium magnets

1) Pot magnets are usually applied with two strengths.

One is vertical force in the vertical direction with stronger holding force;

One is shear force in the horizontal direction with smaller shear force .

2) The pull force of the pot magnet is also related to the roughness of the attached surfaces.

According to customer’s application requirements, our company can produce pot magnets with different sizes, strengths and different accessories.

Features of Round Custom Magnets

1) Small size and powerful function;

2) The strong magnetic force is only concentrated on one side of the pot magnet, and there is almost no magnetism on the other three sides, so the magnet is not easy to break;

3) The magnetic force is five times that of a magnet of the same volume;

4) The pot magnet can attract or move freely on the metal surface;

5) Permanent magnet, long service life.

How is Neodymium Cup Magnets made?

We carry out Magnetic Quality Control of raw materials from suppliers. In our workshop, we produce metal pots with holes, thread bushes, clips, etc., and then glue the magnet and metal pot together to get the pot magnet.

It is not that any random combination of a magnet and a metal pot makes a good performance pot magnet. These pot magnets are out of magnetic circuit design and countless experiments to get their final specifications.

We must guarantee that either the magnet or the metal pot meets all the specifications, As we are ISO 9001- Certified Manufacturer , for which quality system play a major role.

The adhesive we are using was chosen after many tests and comparisons and proved to be most effective in gluing magnets with metal.

We have 15 automatic assembly lines and 8 manual assembly lines to produce pot magnets. With the automatic assembly lines, all the assembly work is computer program controlled to ensure preciseness. With the manual assembly lines, we put in automatic units to cover those key steps to avoid possible man-made errors. We produce millions of pot magnets every year and by using automatic machines we keep stabilized outstanding quality level for all the pot magnets we produce.

More You Want to Know Mounting Magnets

1. What Is The Strongest Magnet?

The strongest permanent magnets in the world are neodymium Magnets, they are magnetic material made from an alloy of neodymium, iron and boron to form the Nd2Fe14B structure.

2. What Is A Cup Magnet?

Cup magnets are magnets inset into steel cups that assist in mounting and increase their holding force. They are commonly used in holding applications where they are attached to a surface with a countersunk screw.

3. How Does A Pot Magnet Work?

A pot magnet works by attaching itself to ferromagnetic materials with the help of its magnetic field. Or to non-ferromagnetic materials with the help of fittings (such as studs and threaded holes) on the top of its steel shell. … The larger the pull force of the pot magnet, the more material it can attract.

Among all our pot magnets we mainly use Neodymium magnet and Ferrite magnet. Where Ferrite is a much weaker magnetic material than Neodymium . But it is much cheaper than NdFeB.

So, to get the same holding force, Pot magnet using Ferrite has a larger diameter than that using NdFeB. Or Selecting the same size of Ndfeb Magnets holding force greater than Ferrite Magents.

As a Professional Magnetic Solutions Provider, WZ Magnetics can customize different Pulling Force according to customers requirements. Welcome to Contact Us at [email protected] !