Precious Metal Melting

Precious Metal Melting

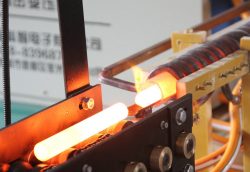

In the industry of gold mining and jewelry making, precious metals’ refining, purification and deep processing are normally of great significance and all need sufficient heating. Thus, one of the most common applications of induction heating machine is to turn the metal into a liquid state so as to meet the strict process requirements of the precious metals. Holding the advantages of rapid heating, environmental protection and energy-saving, JKZ’s induction heating equipment can perfectly complete the process of induction metal melting. To achieve better precious metal melting, such as the induction gold melting, JKZ Electronic has launched a specifically designed CF series of melting furnace. This series can provide effective support for the refining and process of precious metals such as gold and silver. The minimum capacity of this series’ heating devices is 1kg gold. Moreover, with the traits of desktop design, small size and light weight, this series is mainly used for the jewelry casting in the labs. The stationary gold melting induction furnace holds the varied capacity from 4kg to 12kg. The tilting type furnace holds the capacity from 12kg to 100kg, and it is mainly used for the gold bar manufacturing factories. With the optimized circuit design and image, JKZ’s furnaces can also perform advanced human-computer interaction. After simple electricity and water cooling connection, the furnace can rapidly begin to operate.