Precision CNC Machined Parts

Basic Info.Trade Term: EXW,FOB,CIF.CFRPayment Term: T/T,L/C, Western UnionDelivery Time:7-30daysPlace of Origin: Ningbo, China

Information About HEWCHO Precision CNC Machined Parts

Features of precision CNC machined components:

·Product name: Precision CNC Machined Parts

·Material:Carbon Steel, Barss, Copper, Stainless Steel, Alumnum, Titanium Alloy

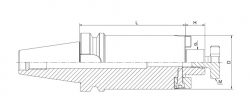

·Machining Tolerances:0.01mm

·Machining Process:

CNC Turning, CNC Milling, Grinding, Threading, Tapping, Bending, Welding, Drilling, Forging

·Min. Order:500PCS

·Surface Treatment: Polishing, Heat Treatment, Sand Blasting, Zinc Plated, Anodization, Chemical Fim,

·Packing: Carton Box, Blister tray, Pallet, Wooden Case.

·Certificate:ISO9001:2008, ISO/TS16949

As a high precision machining parts manufacturer, we provide high precision machined components.

What we can Provide:

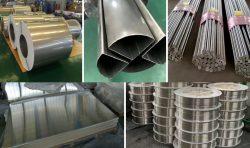

Machining Material:

CNC Machining Service

Carbon Steel

CNC Turning Service

Stainless Steel

CNC Milling Service

Aluminum

Cold Forging Service

Brass

Metal Stamping Service

Copper

Titanium Alloy

Surface Treatment

Application:

Heat Treatment

Automobile Spare Parts

Sand Blasting

Electrical Appliance Industry

Polishing

Electronics Industry

Zinc Plated

General Industry

Anodization

Machinery and Equipment

Chemical Fim

Hydraulic and Pneumatic

Ningbo Hewcho Industrial Limited owns several precision machining lines and can provide precision cnc machining services for a wide range of metal parts according to customer requirements. As one of the leading precision machining suppliers, we offer typical materials include: carbon steel, aluminum, silicon aluminum alloy, titanium alloy, Kovar, copper alloy, magnesium Alloys, copper, stainless steel, etc. We are especially good at parts with small machining tolerances and complicated structures, covering many fields such as electronics, automotive, mechanical heavy industry, aerospace, and semiconductors. The products include: electronic enclosures and covers, electronic components, laser equipment parts, and aerospace Equipment parts, optical parts, mechanical equipment parts, CNC milling parts, pneumatic parts, mechanical parts, communications, semiconductor parts, etc.

The advantages of precision CNC machining

Whether you use our precision machining services alone or, like many other customers, with our precision laser tracking alignment and our laser-guided machining services, you can look forward to all of Metalock’s usual benefits:•Higher machining accuracy•save time and money•A proven solution-oriented approach•Worldwide accessibility•A convenient one stop manufacturer for CNC turning, milling and other technical services you need•Decades of experience – you can safely rely on us when we do your on-site CNC machining