Precision Titanium Machining

Why is Titanium So Hard to Machine?

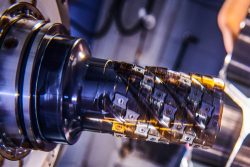

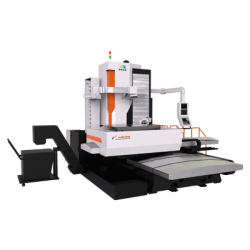

Titanium, as a challenging material, has a unique combination of properties in terms of high strength, high temperature, chemical reactivity, and elasticity. Due to its strength and tendency to harden during processing, it is difficult to cut using traditional machining techniques. Therefore, Swiss machining is the best choice in general.

Falcon Swiss machine shop is an expert in titanium machining and can ensure successful and efficient processing of titanium materials. We have a deep understanding of the unique properties and challenges of titanium and have developed specialized techniques and tools to overcome these challenges. Contact us now for your titanium manufacturing needs!

Advantages of Titanium Materials in Swiss Machining

Titanium is a widely used material in Swiss machining due to its unique properties and numerous advantages. Here are some of the advantages of using titanium materials in Swiss machining:

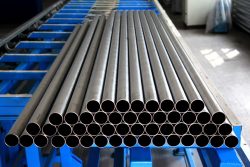

High Strength-to-Weight Ratio: Titanium has an excellent strength-to-weight ratio, making it a popular choice for parts where weight reduction is critical. It is approximately 40% lighter than steel but has similar or greater strength.

Corrosion Resistance: Titanium has excellent corrosion resistance, particularly in harsh environments such as seawater or acidic environments. This property makes it a popular choice in the aerospace and marine industry. Using titanium materials in Swiss machining ensures long-lasting, corrosion-resistant parts.

Biocompatibility: Titanium is biocompatible, meaning it does not react with biological tissues or fluids. This property makes it an ideal choice for medical implants and devices. Swiss machining allows for the precise fabrication of complex medical components using titanium, ensuring a high degree of accuracy and compatibility with the human body.

High-Temperature Resistance: Titanium has a high melting point and can withstand high temperatures without deforming or losing strength. This property makes it suitable for use in high-temperature applications such as jet engines and gas turbines.

Low Thermal Expansion: Titanium has a low coefficient of thermal expansion, which means it expands and contracts minimally with temperature changes. This property is advantageous in applications where dimensional stability is critical, such as precision instruments or optical devices.