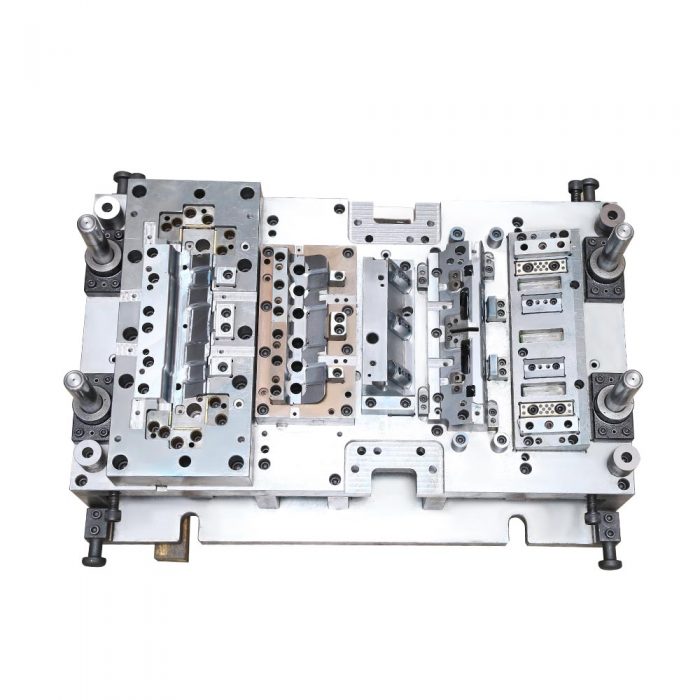

Progressive Stamping Dies

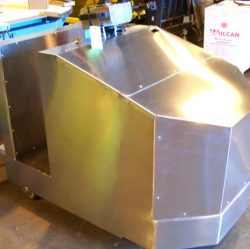

Progressive stamping dies are advanced tools used in metalworking industries to efficiently shape and transform sheet metal into intricate components. These dies play a crucial role in mass production processes by enabling the simultaneous operation of multiple stages within a single press machine.

Designed with precision engineering, progressive stamping dies consist of a series of sequential stations, each performing a specific operation on the sheet metal as it advances through the die. These stations can include cutting, bending, forming, coining, and more. The continuous and automated nature of progressive stamping significantly speeds up production while maintaining high precision and consistency in the manufactured parts.

The complexity of progressive stamping dies varies based on the intricacy of the part being produced. Highly skilled tool and die makers meticulously design these dies to ensure proper alignment, tolerances, and smooth material flow. This results in efficient material usage, reduced waste, and improved overall production efficiency.

Industries ranging from automotive to electronics, appliances, and beyond benefit from the advantages of progressive stamping dies. They offer cost-effective solutions for producing large quantities of complex parts with minimal manual intervention, leading to lower labor costs and increased production rates.

In conclusion, progressive stamping dies are integral to modern manufacturing processes, driving efficiency, precision, and high-volume production of intricate sheet metal components across a multitude of industries.