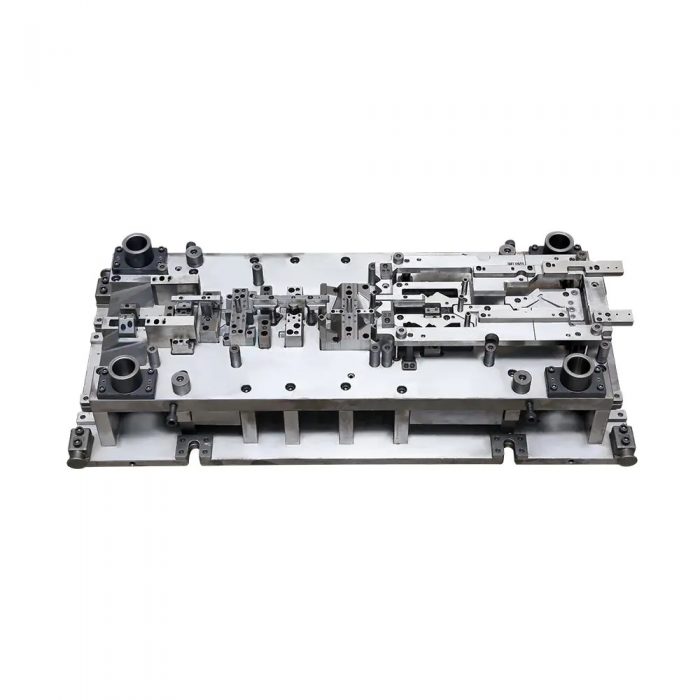

Progressive stamping dies

Progressive stamping dies are essential tools used in the manufacturing industry for the high-volume production of intricate metal parts. These dies are designed to efficiently produce multiple operations on a single sheet of metal, resulting in faster production times and improved productivity.

The progressive stamping process involves feeding a continuous strip of metal through a series of stations within the die. Each station performs a specific operation, such as punching, bending, or forming, gradually transforming the raw material into a finished part. The progressive nature of the dies allows for continuous and automated production, minimizing manual intervention and increasing efficiency.

One of the key advantages of progressive stamping dies is their ability to create complex parts with high precision and consistency. The dies are engineered to ensure accurate positioning and alignment of the metal strip, resulting in uniform and repeatable part dimensions. This makes them suitable for applications that require tight tolerances and intricate designs.

Furthermore, progressive stamping dies offer cost savings in terms of material utilization and labor. The efficient utilization of the metal strip minimizes waste, while the automated process reduces the need for manual labor and increases production output. These factors contribute to lower production costs and improved profitability for manufacturers.

Overall, progressive stamping dies are a crucial tool in the manufacturing industry, enabling efficient and cost-effective production of intricate metal parts. With their ability to handle high volumes, maintain precision, and optimize material utilization, these dies play a vital role in meeting the demands of modern manufacturing processes.