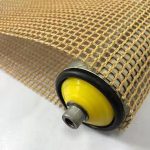

PTFE Kevlar Conveyor Belt

In the 1960s, DuPont developed a new type of arylene fiber composite —- arylene fiber 1414, which was commercialized and registered as Kevlar in 1972. Models include K29, K49, K49AP and so on.

Because this new material density is low, high strength, good toughness, high temperature resistance, easy to process and molding, its strength is 5 times the same quality of steel, but the density is only one fifth of steel (Kevlar density is 1.44 grams per cubic centimeter, steel density is 7.859 grams per cubic centimeter), and people’s attention. Because the material of kevlar brand products is tough and wear-resistant, rigid and soft, with special ability of invulnerability. It is called “armored guard” in military.

Very low friction coefficient (0.05-01) is the best choice for oil free self-lubrication.

All poison has been FDA, European LFGB food testing certification and approved widely used in food processing, packaging and other processing fields.

Microwave resistance, high frequency, purple, infrared resistance.

Specifications Of PTFE Kevlar Conveyor Belt

Product model

color

Maximum width (mm)

thickness0.01mm

g

PTFEcontent(%)

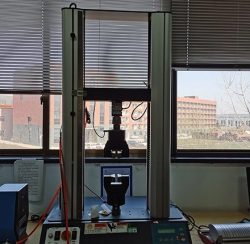

Tensile strength(N/5CM)

note

Product model

color

1250

7.5

150

67

550/500

TKL9008AJ

Brown

1250

7.5

150

67

630/600

TKL9008J

Brown

1250

6.5

70

30

520/500

breathable

TKL9008BJ

Black

1250

8

170

71

550/500

antistatic

TKL9008B

Black

1250

8

165

70

550/500

TKL9010T

White

1250

10

130

20

800/800

breathable

TKL9010G

White

1250

11

220

53

1000/900

Coarse grid lines

TKL9011A

White

1250

11

220

53

1000/900

TKL9011AJ

Brown

1250

11

220

53

1000/900

TKL9012AJ

Brown

1250

12

240

57

1000/900

TKL9013A

White

1250

13

260

60

1000/900

TKL9013AJ

Brown

1250

13

260

60

1200/1100

TKL9013BJ

Black

1250

12.5

240

57

800/800

antistatic

TKL9013B

Black

1250

12.5

250

58

800/800

TKL9015AJ

Brown

1250

15

310

66

1200/1000

TKL9018AJ

Brown

1250

18

370

57

1800/1600

TKL9020AJ

Brown

1250

20

410

61

1800/1600

TKL9023AJ

Brown

2800

23

490

59

2200/1900

TKL9025A

White

2800

25

500

60

1400/1100

TKL9025AJ

Brown

2800

25

530

62

2500/1900

TKL9025BJ

Black

2800

23

500

60

1400/1100

antistatic

TKL9025B

Black

2800

23

500

60

1400/1100

TKL9030AJ

Brown

2800

30

620

53

2500/2000

TKL9030BJ

Black

2800

30

610

52

2100/1800

TKL9030B

Black

2800

30

580

49

2100/1800

TKL9035BJ

Black

2800

35

660

62

1800/1500

antistatic

TKL9035B

Black

2800

35

660

62

1800/1500

TKL9035AJ

Brown

2800

35

680

63

2700/2000

TKL9035AJ-M

White

2800

36

620

59

2500/1800

Smooth on one side and rough on the other

TKL9038BJ

Black

2800

38

720

65

2500/1600

antistatic

TKL9040A

White

2800

40

770

57

2700/2150

TKL9040Hs

Gray

1600

40

540

25

3500/2500

single

TKL9050HD

Gray

1600

48

620

45

3250/2200

Double sided

TKL9055A

White

2800

53

990

46

3800/3500

TKL9065A

Brown

2800

65

1150

50

4500/4000

TKL9080A

White

2800

85

1550

55

5200/5000

TKL9090A

White

2800

90

1600

52

6500/5000

TKL9100A

White

2800

105

1750

55

6600/6000

Highlight Of PTFE Kevlar Conveyor Belt

Climate: it can be used for a long time in a wide temperature range of -60℃~300℃. It can be placed continuously for 200 days under the high temperature of 300℃ for aging test, not only the strength will not be reduced. And there’s no loss of weight. It does not crack under the ultra-low temperature of -180℃, and can maintain the original softness, and it can work for 120 hours under the ultra-high temperature of 360℃, without aging, cracking and good softness.

Non-adhesion: paste, sticky resin, organic coating and almost all sticky substances can be easily removed from the surface.

Mechanical properties: the surface can withstand compression load 200Kg/cm2 after the basic deformation, lack of roll. With very low friction coefficient, excellent dimensional stability, tensile resistance s5%.

Electrical insulation: with unique electrical insulation, dielectric constant 26 dielectric loss tangent below 0.0025.

Corrosion: can resist the corrosion of almost all pharmaceutical items, in strong acid, strong alkali conditions, no aging and deformation.