RFID Inlay

RFID dry inlay is an important material in the production process of RFID products. Normally, rfid inlay tag consists of microchip, antenna and substrate. As a core part of all kinds of RFID products, RFID inlay quality directly affects the reliability and performance of the finished RFID Tags. As one of the rich experience rfid inlay manufacturers, rfid inlay suppliers, DTB is very familiar with RFID inlay production technology. We can design and produce RFID inlay which is suitable for various industrial environments and applications according to customer needs.

RAIN/UHF RFID Inlay

RAIN/UHF RFID Inlay is the microchip and antenna core of an RFID tag which uses Radio frequency identification passive (battery-free) wireless technology system to identify and track objects.

HF/NFC RFID Inlay

With a wide selection of antenna choices and protocols, DTB HF inlays offer great application flexibility and fit-for-function design in the most demanding applications.

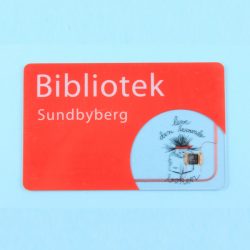

RFID Card Prelam

DTB RFID designs various kinds of RFID prelam to meet different layout standards. The prelam edge made by DTB RFID is neat, the surface is smooth and flat, and the chip position is neat and consistent.

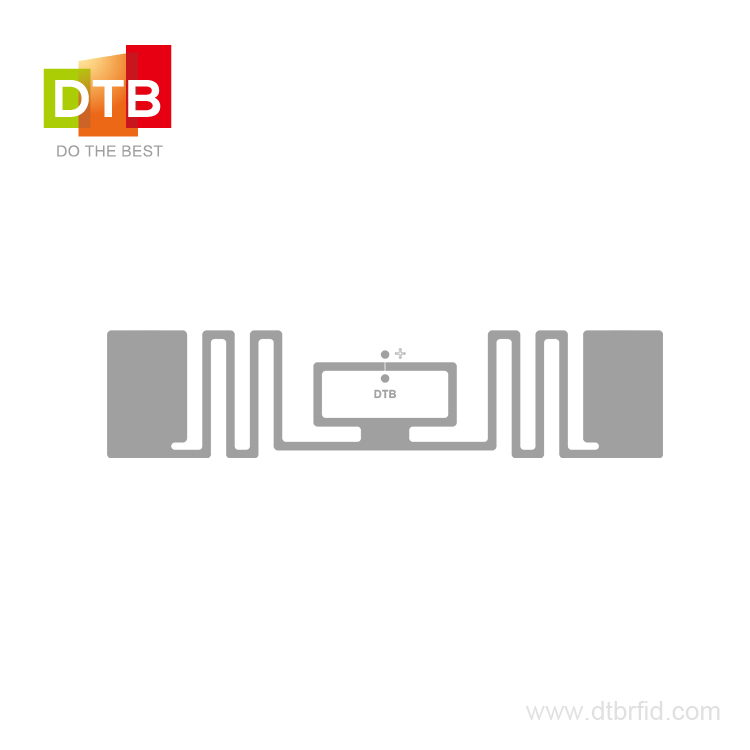

DTB-M70 Dry Inlay

Description of DTB-M70 Dry Inlay

Air interface protocol

EPC Global Class1 Gen2 ISO 18000-6COperational frequency

Global 860-960MHzTag dimensions70x14mm / 2.76″x0.55″

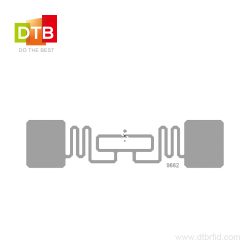

DTB-R40 Wet Inlay

Description of DTB-R40 Wet Inlay

Air interface protocol

EPC Global Class1 Gen2 ISO 18000-6COperational frequency

Global 860-960MHzTag dimensions43x18 mm/1.69″x0.71″

DTB-R50 Wet Inlay

Description of DTB-R50 Wet Inlay

Air interface protocol

EPC Global Class1 Gen2 ISO 18000-6COperational frequency

Global 860-960MHzTag dimensions52x33mm / 2.05″x1.30″

DTB-R70 Label

Description of DTB-R70 Label

Air interface protocol

EPC Global Class1 Gen2 ISO 18000-6COperational frequency

Global 860-960MHzTag dimensions73x20mm / 2.87″x0.79″

DTB-U50A

Description of U50AAir interface protocol

EPC Global Class1 Gen2 ISO 18000-6COperational frequency

Global 860-960MHzTag dimensions43x18 mm/1.69″x0.71″

Custom RFID Inlay Manufacturer

In addition to RFID dry inlay and RFID wet inlay, DTB also offers RFID prelam in various sizes and thicknesses. For the RFID prelam, DTB uses advanced laminating equipment.

In the production process, each production technical parameter conforms to the ISO7810 standard, which makes the finished prelam bond firmly. We have automated wire planting technology and touch welding technology, which makes the performance of RFID prelam very stable.

Main Application of RFID Inlay

Logistic management

Retail management

Medicine management

Library management

Transportation Laundry

Types of RFID Inlay Production

RFID Inlay by Frequency

LF RFID Inlay(125KHz/134.2KHz)

HF/NFC RFID Inlay(13.56MHz)

UHF/Rain RFID Inlay(860~960MHz)

RFID Inlay by Structure

RFID dry inlay: chip + antenna + substrate PET;

RFID wet inlay:chip + antenna + substrate PET + glue + release paper;

RFID prelam:Substrate PVC + chip + antenna + Substrate PVC.

https://www.dtbrfid.com/products/rfid-inlay/