Shuttering Magnets

Introduction of Shuttering Magnets

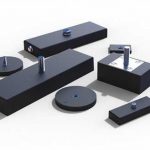

The Precast Shuttering magnet is consist of NdFeB magnet, Steel housing, Magnet plate and Knob. where the knob goes through the center of steel housing and magnet plate to connect them together. By assembling the strong neodymium magnets with the steel housing, we can achieve great holding force up to 2100kgs.

Precast shuttering magnets are an essential tool for construction projects as they can hold a force up to 2100 kgs. They are used for holding up precast concrete elements during their production and installation process. By using precast shuttering magnets, the construction process is made easier and safer as it eliminates traditional formwork tasks. Additionally, these magnets require minimal maintenance which makes them more cost-effective compared to other solutions.

Precast Formwork Magnets Product Information:

Large range of magnets for precast from small magnetic nailing plate, magnetic ferrule to large magnetic shuttering and profile systems are available.

Custom request on design, strength and coating etc can be provided.

Easy operation and great reliability.

In the past, construction fields usually used screws or pins to fix concrete mold. It takes much more time to drill holes for the pins and screws. After the concrete is formed, it also needs people to detach the fixation. This is really inefficient labor.

Let’s go to together to find how easy to use and release the shuttering magnets. Step on the knob to attach and then use a lever to release, then it is settled. And by using magnets there is no need for drilling holes so that it will save a lot of time, besides the mold table could have a longer life.

How to operate a precast shuttering magnet?

Please visit our Youtube Channel: How to operate a shuttering magnet?

The surface treatment of shuttering magnet is able to be customized. Like zinc plating, epoxy coating, blackening, or using stainless steel without plating etc. And the vertical holding force of our shuttering magnets vary from 450kgs to 2100kgs which can fully satisfied customers different requests.

Except shuttering magnets, we also have various kinds of magnets could be used in precast concrete constructions, like NdFeB magnetic fixing plate for socket system, NdFeB magnetic nailing plate, Concrete Insert Magnts, Magnetic Recess Former for foot anchor or other anchor, and tube magnet etc.

Tips for using precast concrete shutting magnets

1. Wear protective gloves and shoes when working with large magnets. Strong magnetic force is also very dangerous. Improper operating could cause crushing injury of fingers or skin, or even fractures.

2. Magnets should be kept away from electronic devices such as pacemakers, cell phonse, watches, computers, credit cards, etc. The Magnetic Fields may damage these things.

3. Avoid rough handling with hammer as the magnets may break.

4. Magnets should be maintained after use, such as cleaning out concrete, dirt, debris, and keeping the magnetic surface clean and smooth. If possible, the surface should be coated with oil to prevent rust.

5. The magnet should be used and stored below 80℃, otherwise the magnetic force will decrease or disappear.

6. Stock the magnet in a dry and clean environment to prevent rust and corrosion.