Slewing Ring Bearing With External Gear

Slewing Ring Bearing With External Gear

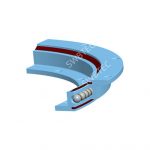

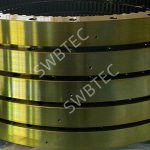

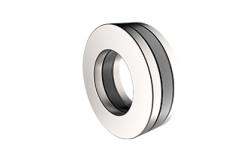

Slewing Ring Bearing With External Gear is with gear on the external ring, it is processed by a gear shaping machine. Customer can prefer the gear hardening treatment or not according to the working condition, if it need high load and press, we advise to do hardening treatment. Due to the gear is on the outer ring, it can maximized the use of the limited space of the slewing ring and it is very easy to check the gear engagement and failure diagnosis. Another advantage is due to the large pitch circle diameter of the outer gear, it can be better to achieve a larger transmission ratio and greatly reduce the circuar force and torque to the related pinion.

Slewing Ring Bearing With External Gear Features and Benefits

Regarding the problems of the slewing bearing teeth in the work, we have not received any complaints from customers in recent years, because our procedure technology of slewing bearing with internal gear and slewing bearing with external gear is very mature for the processing of teeth, especially the heat treatment of teeth.

The quenching of the teeth includes surface quenching, root tooth & surface quenching and full quenching.

The surface hardness of the quenched part is 50-60HRC, and the depth of the effective hardened layer must also meet the corresponding requirements according to the size of the teeth, and there should be no cracks on the surface of the tooth after hardening treatment.

We have been inspecting each set of products in strict accordance with the customer drawing requirements.