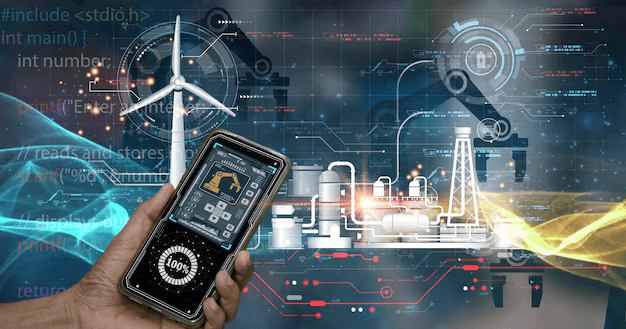

Smarter PVDF Pump Monitoring with AI And IoT

PVDF pumps are trusted in chemical, pharmaceutical, and water treatment industries for their durability and resistance to corrosive liquids. Yet, even robust pumps face issues like wear, downtime, and high maintenance costs. By integrating Artificial Intelligence (AI) and the Internet of Things (IoT), pump monitoring becomes smarter, predictive, and more efficient.

IoT sensors continuously measure flow, pressure, vibration, temperature, and energy use, providing real-time visibility into pump performance. AI analyzes this data to detect anomalies, predict failures, and suggest proactive maintenance, reducing costly breakdowns.

The result is enhanced efficiency, reduced downtime, improved safety, and optimized energy consumption. Smarter monitoring also supports sustainability goals by extending pump lifespan and minimizing waste.

For industries where reliability is critical, AI- and IoT-powered PVDF pump monitoring marks a shift from reactive repairs to predictive intelligence, paving the way for safer, smarter, and future-ready operations.