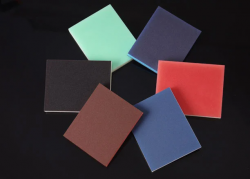

Special Treated White Fused Alumina

Special treated white fused alumina is made of high-quality fused alumina as the raw material. After high temperature and high heating, a layer of metal iridium composite material is plated on the surface of the material, and the special treated abrasive is made after calcination. After the fused alumina coated with iridium, the toughness is significantly improved, the surface is rougher, the hydrophilic ability is stronger, the self-sharpening property is increased, and the heat dissipation performance is improved. The abrasive products have the characteristics of high efficiency, long life, and not easy to burn the workpiece.

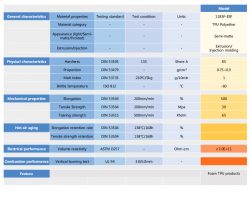

Description of Special Treated White Fused Alumina

Items

Unit

Index

Typical

Chemical Composition

Al2O3

%

99.00min

99.32

SiO2

%

0.20max

0.09

Fe2O3

%

0.10max

0.03

Na2O

%

0.40max

0.23

Refractoriness

℃

1850min

Bulk Density

g/cm3

3.50min

Mohs Hardness

—

9.00min

Principal Crystalline Phase

—

α-Al2O3

Refractory Grade

Grain

mm

0-50, 0-1, 1-3, 3-5, 5-8

Fines

mesh

-200, -325

Grit (F Grade and P Grade)

FEPA

8, 14, 16, 20, 22,24, 30, 36, 40, 46, 60, 70, 80, 90, 100, 120, 150, 180, 220, 240

Typical Physical Properties of Special Treated White Fused Alumina

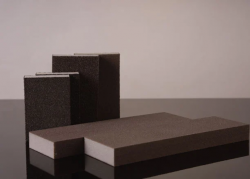

01.

New Materials

Specail treated fused alumina abrasives are based on traditional abrasives, using new materials and technologies to improve the abrasive.

02.

Hydrophilicity

Compared with ordinary abrasives, the microhardness is increased by 10%, the toughness is increased by 10%, the hydrophilicity is increased by 35%, the grinding efficiency is increased by 30%, and the durability is increased by 30-50%, which is very helpful for the improvement of the quality of grinding wheel products.

03.

Raw Materials

Special treated fused alumina can also be used in precision casting molding sand, spraying materials, raw materials for special ceramic products, advanced refractory materials and other fields.