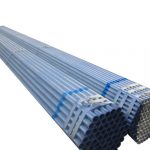

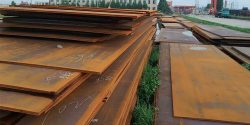

Spiral Tube

SSAW steel pipe is made up of hot-rolled coiled steel using a double-sided submerged arc welding method. The welding process allows the steel pipes manufacturers to produce large-diameter steel pipes suitable for different applications.

Specification of Spiral Tube

Standard

API 5L PSL1, ASTM A53, ASTM A252, SY/T5037, SY/T5040, DIN 30670

Material

ASTM A252 GR.1—3, SS400, ST37, ST52, Q235, Q345, API GR.A, GR.B

Specification

OD: 219.1mm-2320mm

Wall thickness

5mm-24mm

Surface treatment

Galvanized, 3-LAYERS PE, FBE, lacquering, varnishing

Features of Spiral Tube

SSAW steel pipe can be produced in longer length (maximum length up to 50 meters) compared to LSAW steel pipes.

Due to its spiral seam SSAW pipe has an accurate diameter accuracy and strength.

The sizes are adjustable & can be tailored to end-user requirements.

Main usage: oil and natural gas transportation pipeline project、Refining Pipeline project、urban water supply and drainage project.