Steel Mesh Grating

Mesh Grating Description

Steel mesh grating is made by welding with flat steel as well as bars with certain distances. it goes through cutting, opening, bordering and other process.

steel mesh grating is resistance-welded for toughness, strength and security making use of an automated electric/ hydraulic welding process. High temperatures, combined with high pressure, fuse the bearing bars and go across bars together to develop a long-term joint.

The mix of heavy-weight bearing bars and turned steel cross bars give outstanding grating stability and loading capacities. The cross bars are welded or electro-forged to the rectangle-shaped designed bearing bars by a process that integrates intense hydraulic pressure with a powerful electric existing.

Steel Mesh Grating Chuangxin Features

The products enjoy the features of high strength, light structure, high bearing.

Mesh Grating Application

The most widely used gratings, available for flooring, sidewalk, drainage cover, stair tread.etc.

It is widely used in the platform, corridor, bridge, well covers, stairs, fencing for petroleum, chemical, power plant, wast treatment plant, civil engineering projects and environmental projects

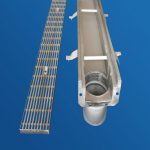

Rain Water Steel Grating Installation Notes:

(1) T type- Rain Water Steel Grating for ordinery side ditch and transverse

1. The anchor parts of the frame must be firmly embedded in the cement layer;

2. The supporting surface on the opposite side of the ditch must be smooth and solid.

(2) U type- Rain Water Steel Grating for U type ditch

Iron Angle will be the main support of the whole grille cover, the iron Angle of the grille cover must be smooth and firm.

(3) M type- Rain Water Steel Grating for borehole

1、The support surface of borehole cover must be smooth and solid, and as close as possible to the frame.

2、Anchors must be firmly embedded in cement or bitumen layer

Yeah this is one of the most requested feature from the community https://www.myiclubonline.onl/