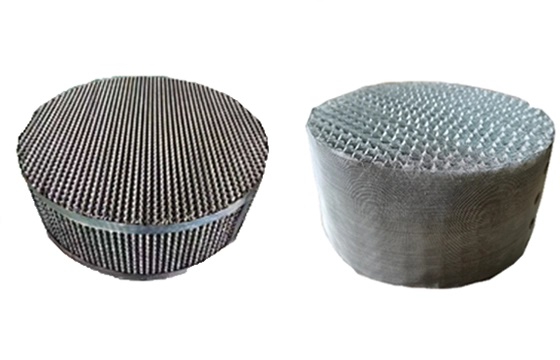

Structured Packings

Accurate, stable and optimized distillation process and cost-effective tower packing manufacturing base.

Technical Principle Of Structured Packing In Distillation Column

Characteristics of Structured Packing

1

Compared with conventional structured packing, the pressure drop of DODGEN high-efficiency structured packing in distillation column is greatly reduced under the same efficiency, and the capacity can be increased by up to 40% under the same HETP

2

As one of structured packing manufacturers, DODGEN’s high-efficiency structured packings is suitable for the separation case from vacuum to medium pressure, and even for the high-pressure case in some applications;

3

Low-pressure drop for DODGEN structured packing in distillation column, the pressure drop of each theoretical plate is only 0.3 ~ 1.0 mbar under normal conditions, and only 2.0 mbar at 70% ~ 80% flooding rate;

4

DODGEN high-efficiency structured packing has good operating turndown and can be applied to working conditions with liquid load range from 0.2 m3 / m2h to 200 m3 / m2h;

5

As one of the chemical reactor manufacturers, DODGEN high-efficiency structured packing can break the capacity bottleneck of existing trays and random packing.

Applications of Structured Packing

Chemical industry: OLEO, flavors & fragrances, Ethylbenzene (EB) / Styrene Monomer (SM), cyclohexanone / cyclohexanol, air separation

Petrochemical Industry: quench tower, C3 and C4 separation tower, xylene separation tower

Oil refining unit: Crude Oil tower, vacuum tower

Absorption and desorption: natural gas dehydration, CO2 and H2S absorption and stripper, ethylene oxide(EO) absorption and stripper, acrylonitrile absorber.